-

BOMBARDIERIMore information

BOMBARDIERIMore information

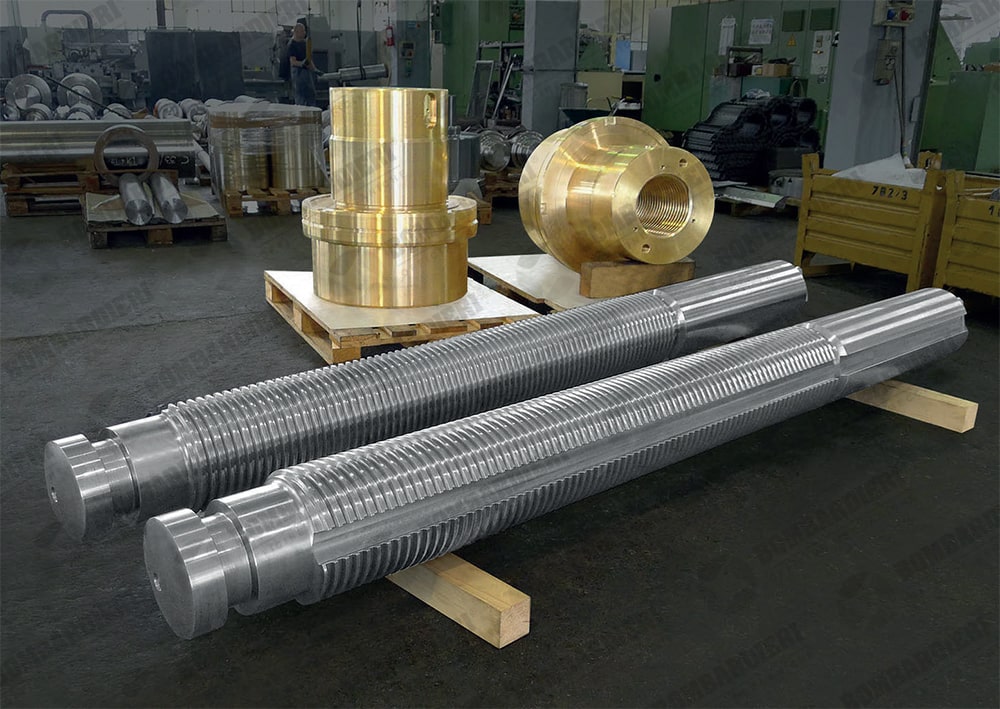

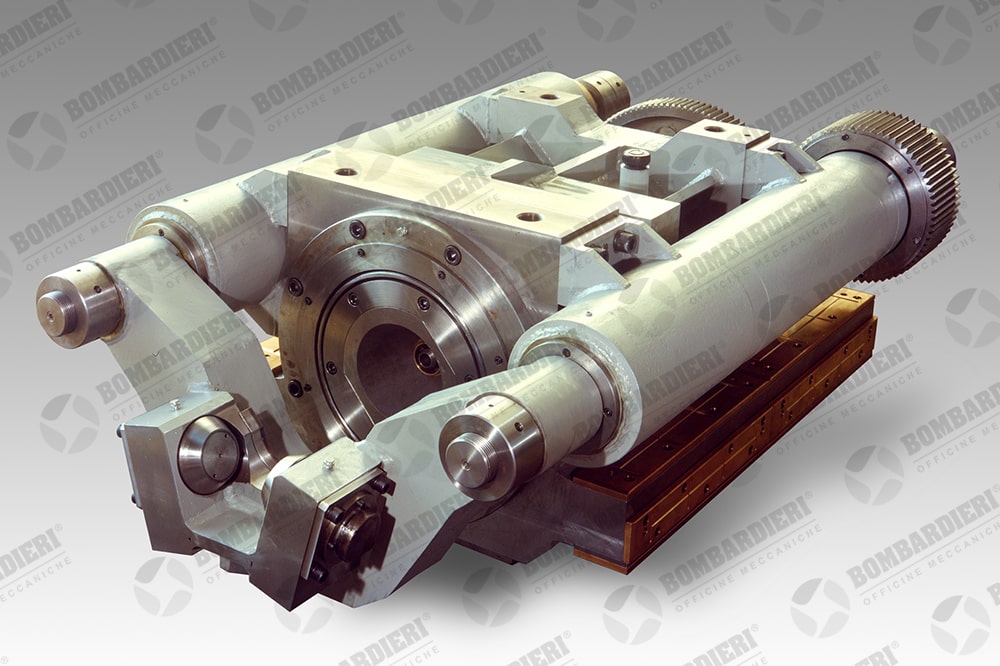

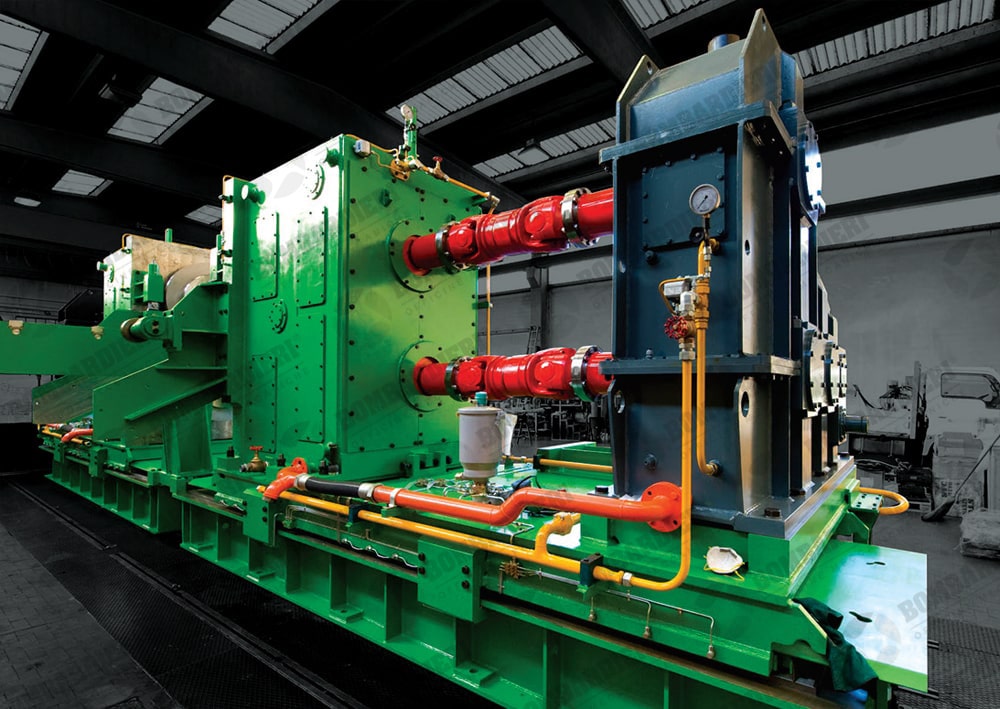

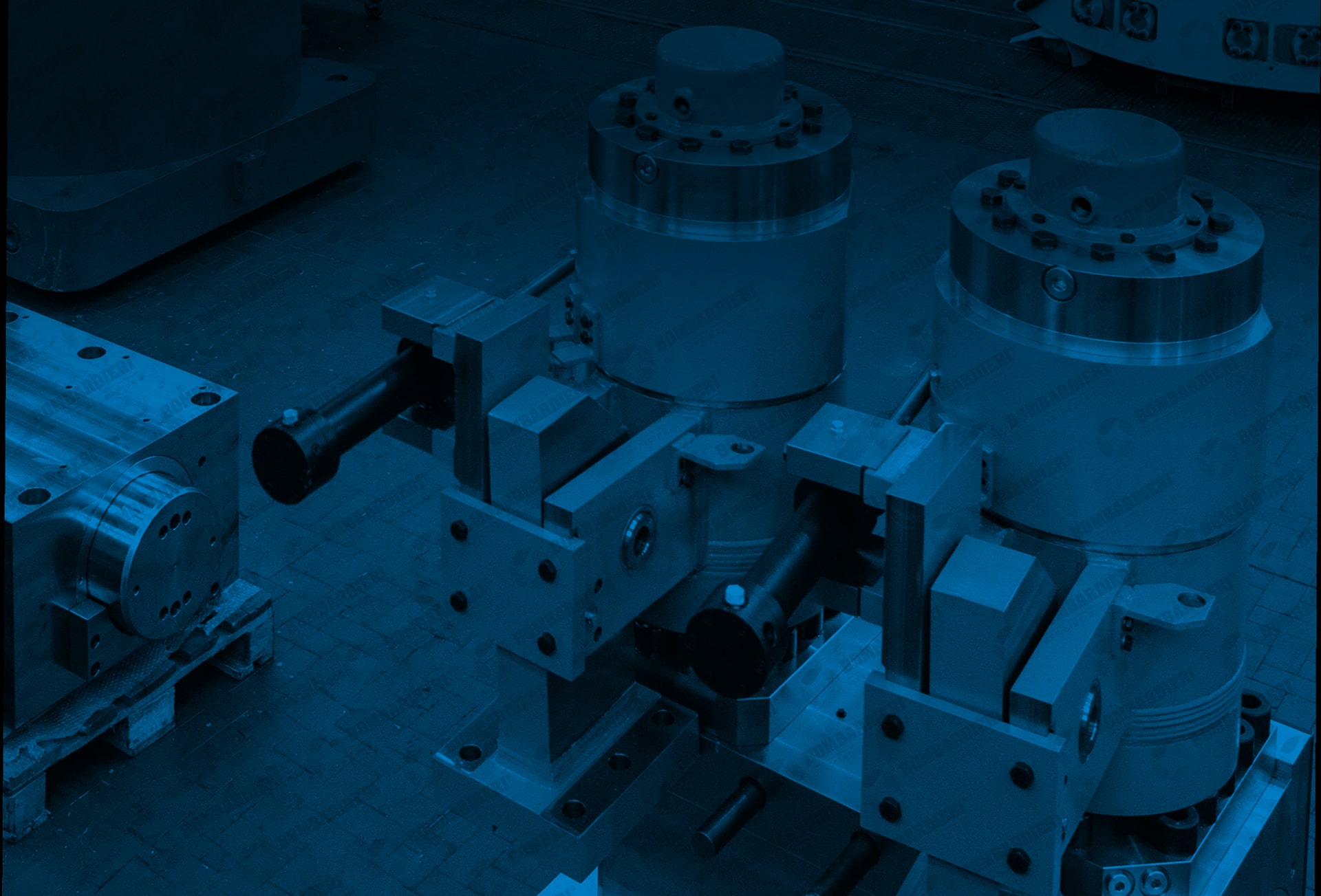

SPARE PARTS AND ASSEMBLIES

FOR ROLLING MILLS AND PIPE MILLS0102 -

BOMBARDIERIMore information

BOMBARDIERIMore information

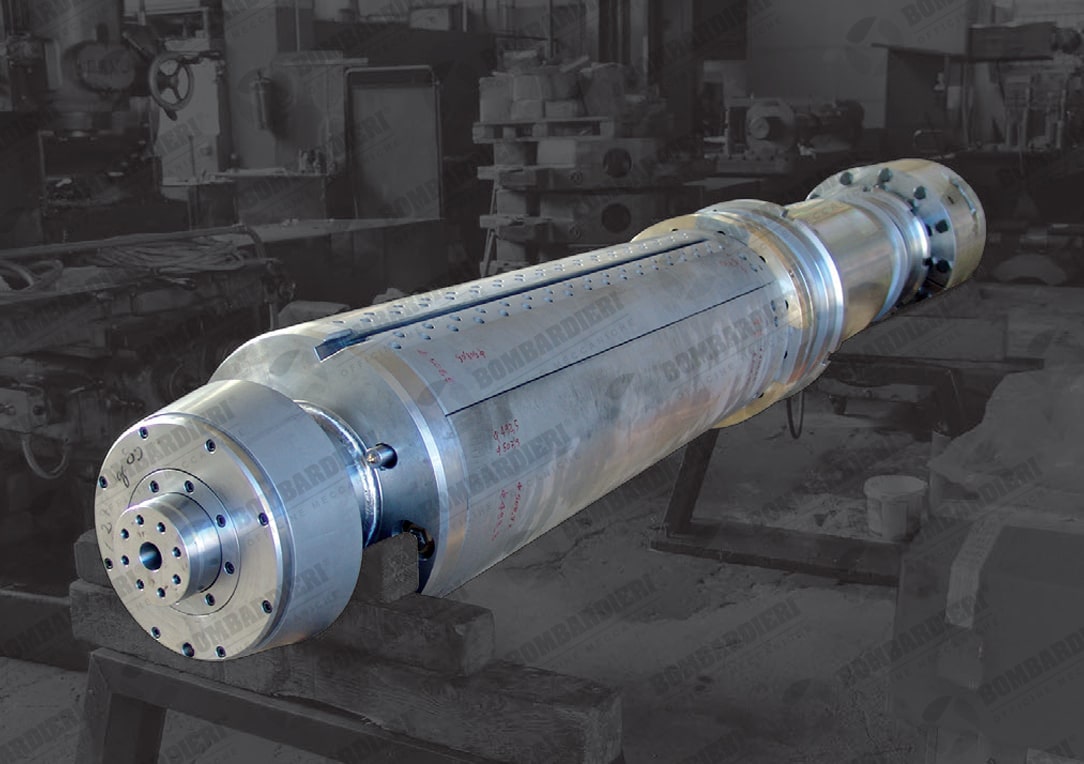

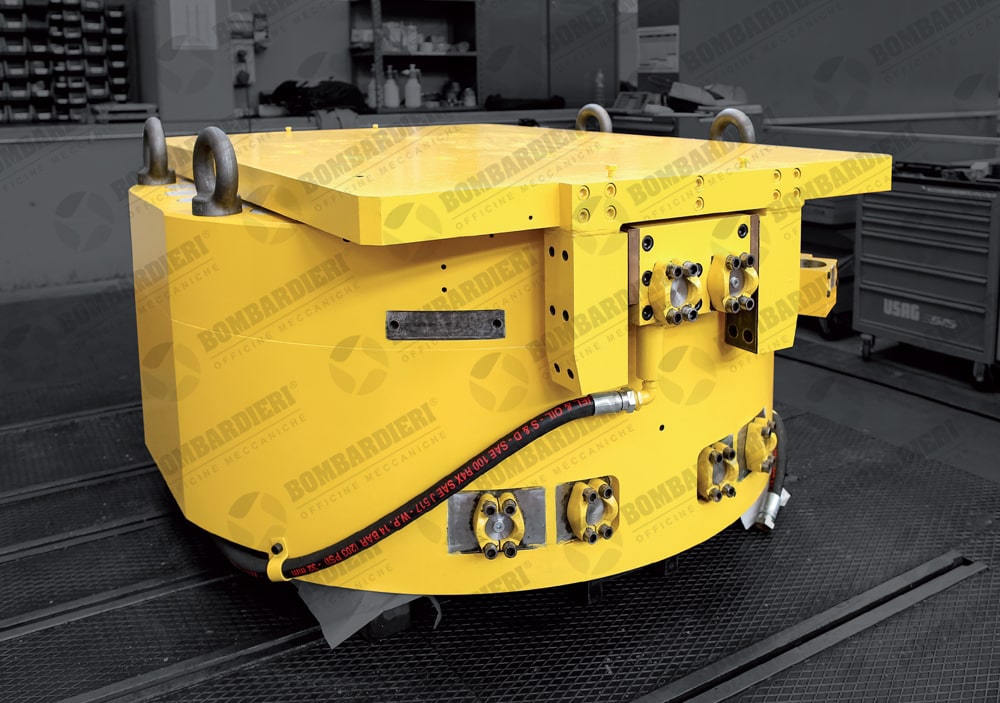

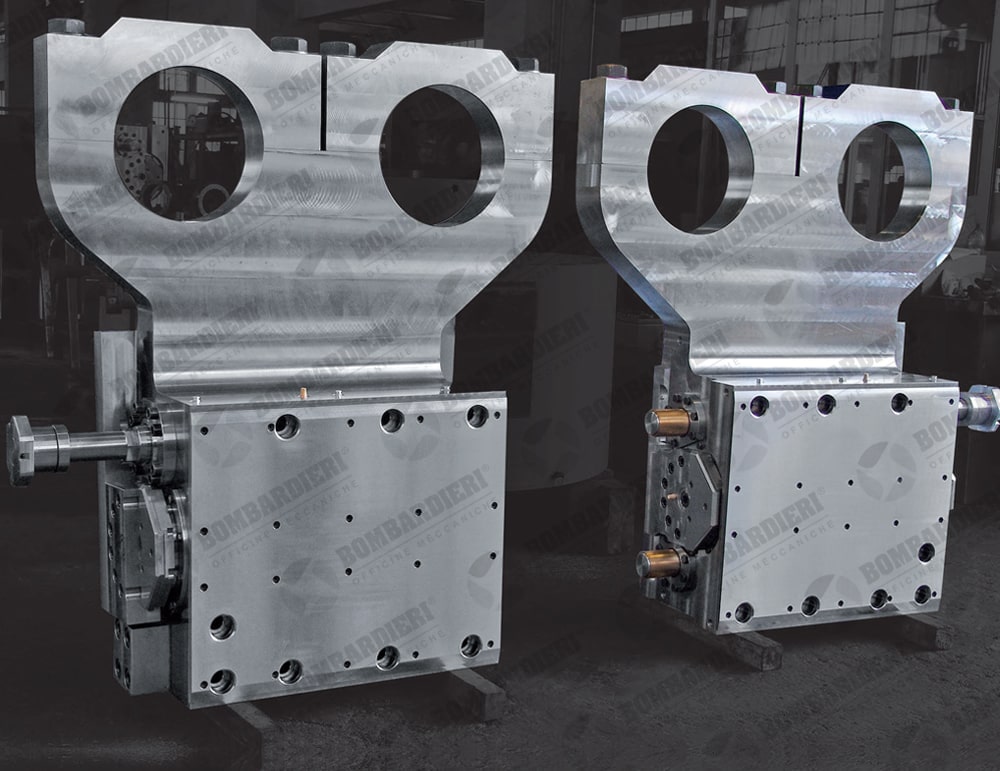

SPARE PARTS AND ASSEMBLIES

FOR PIPE MILLS0201

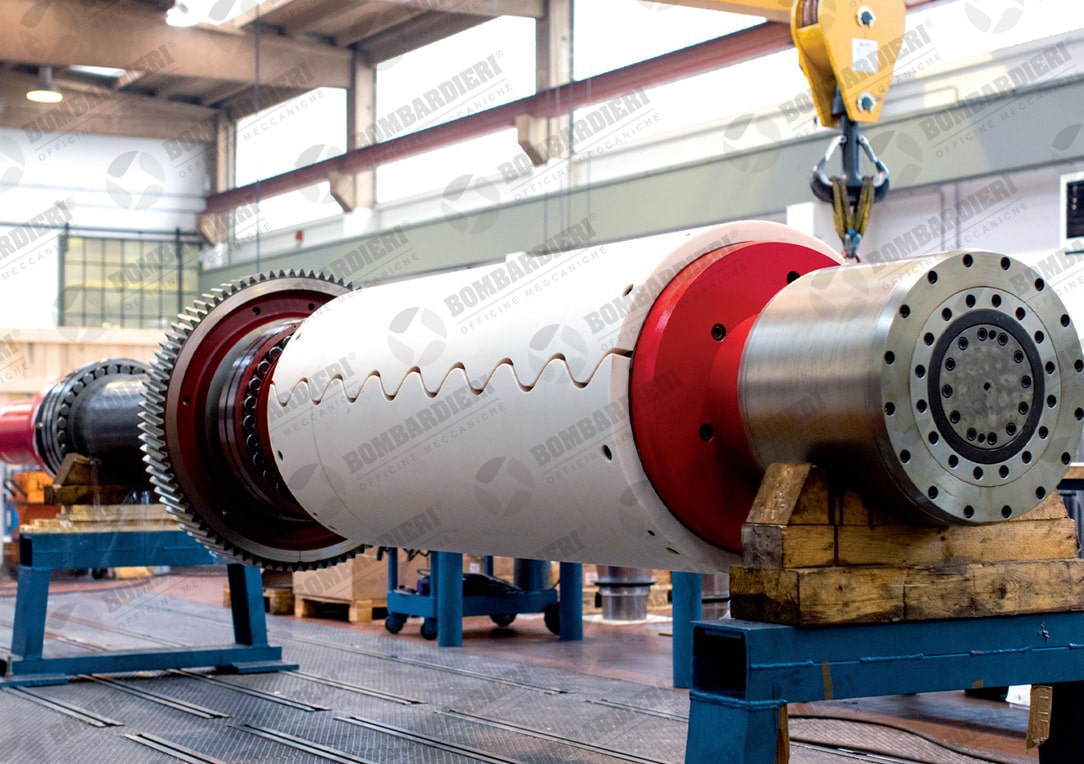

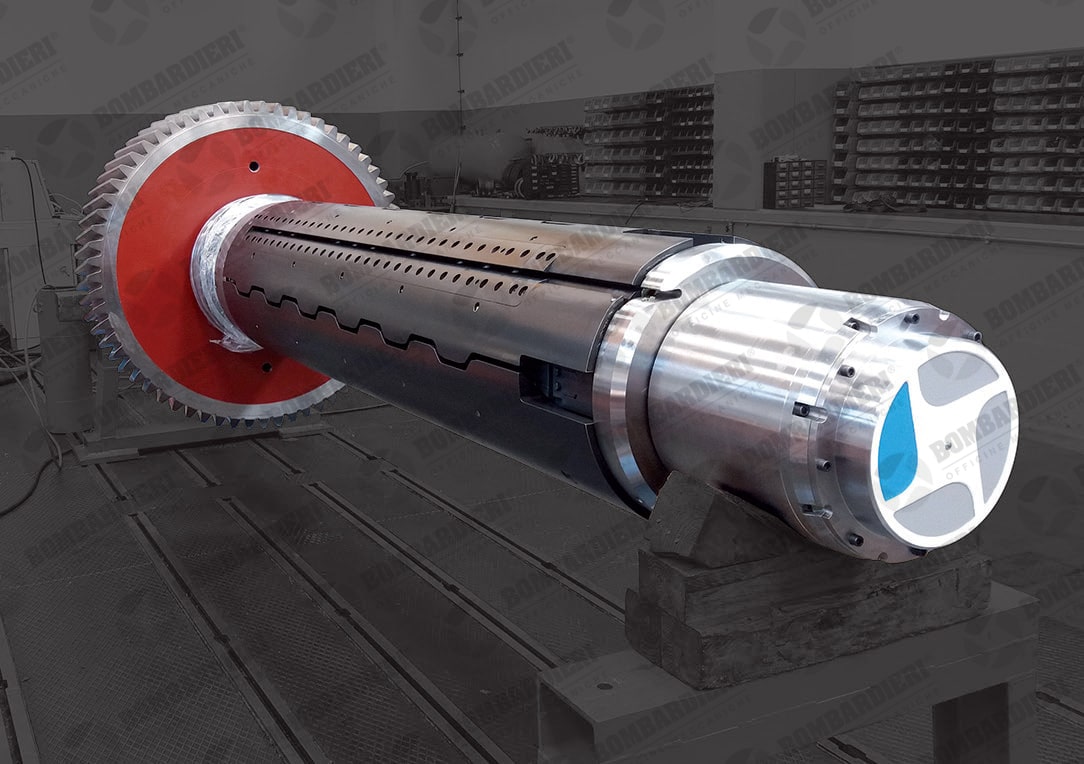

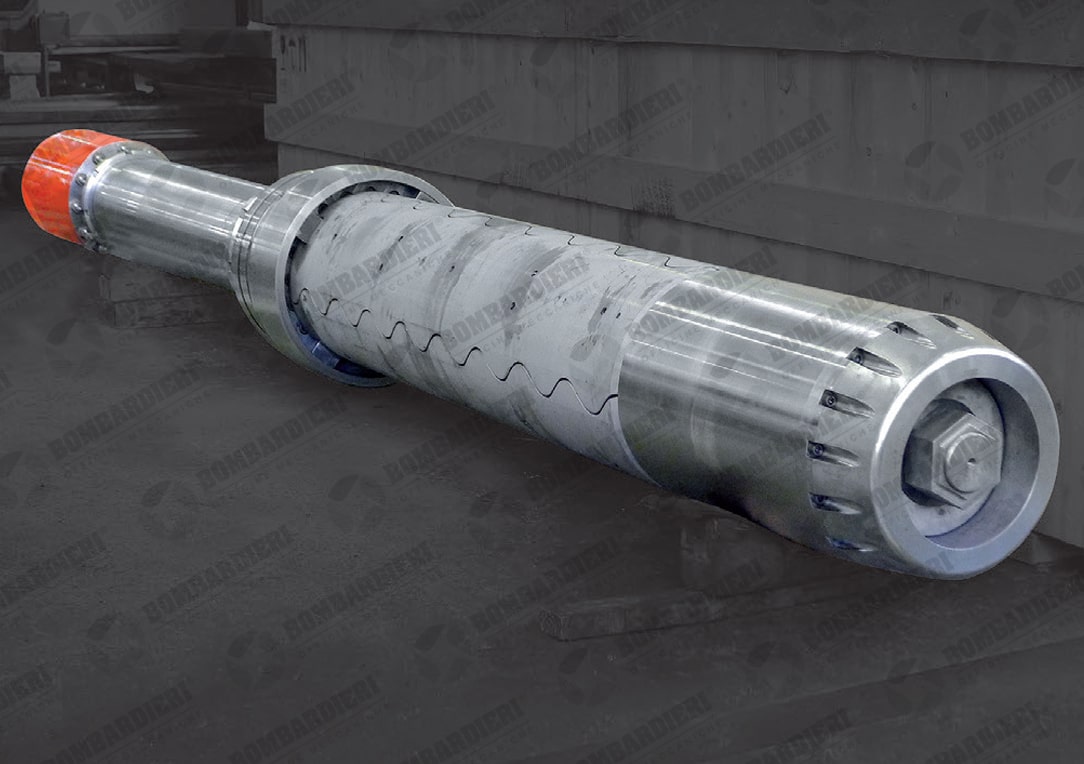

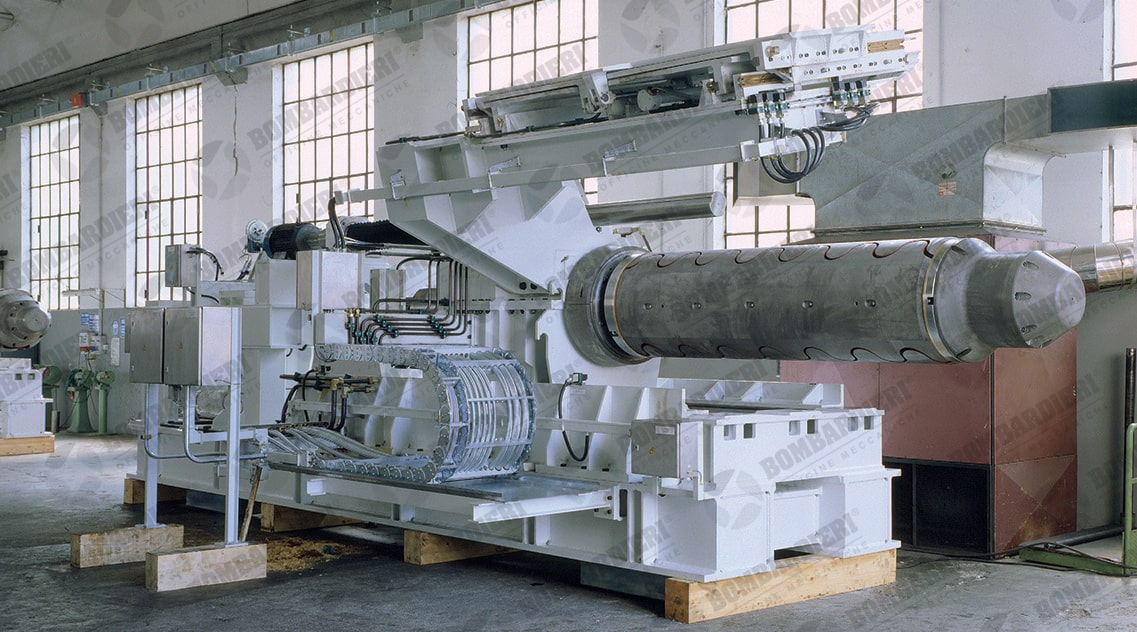

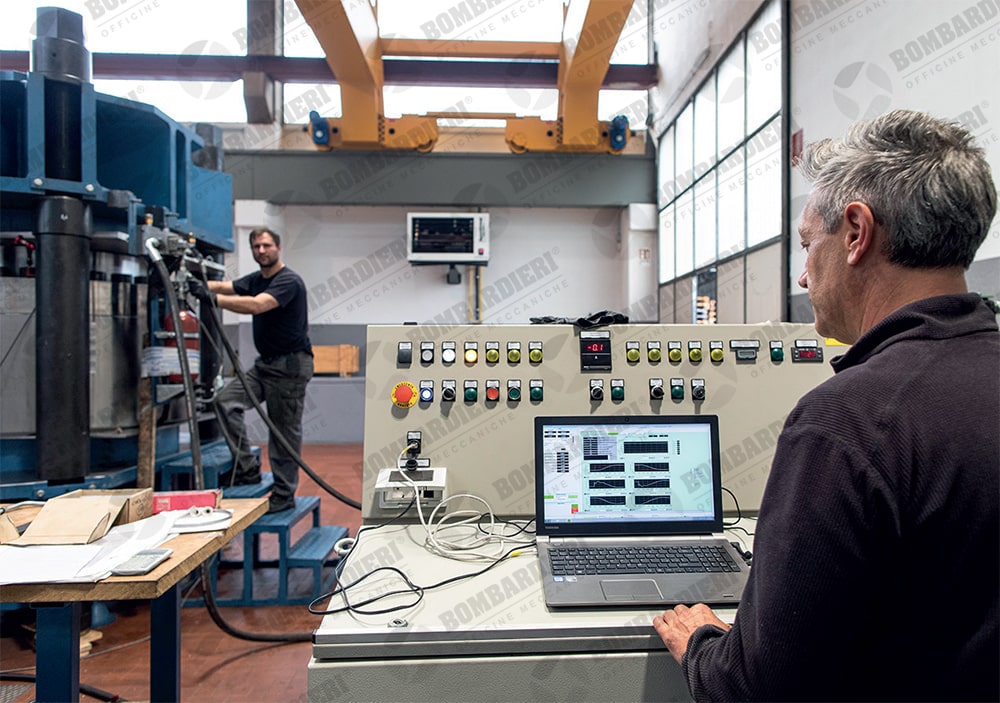

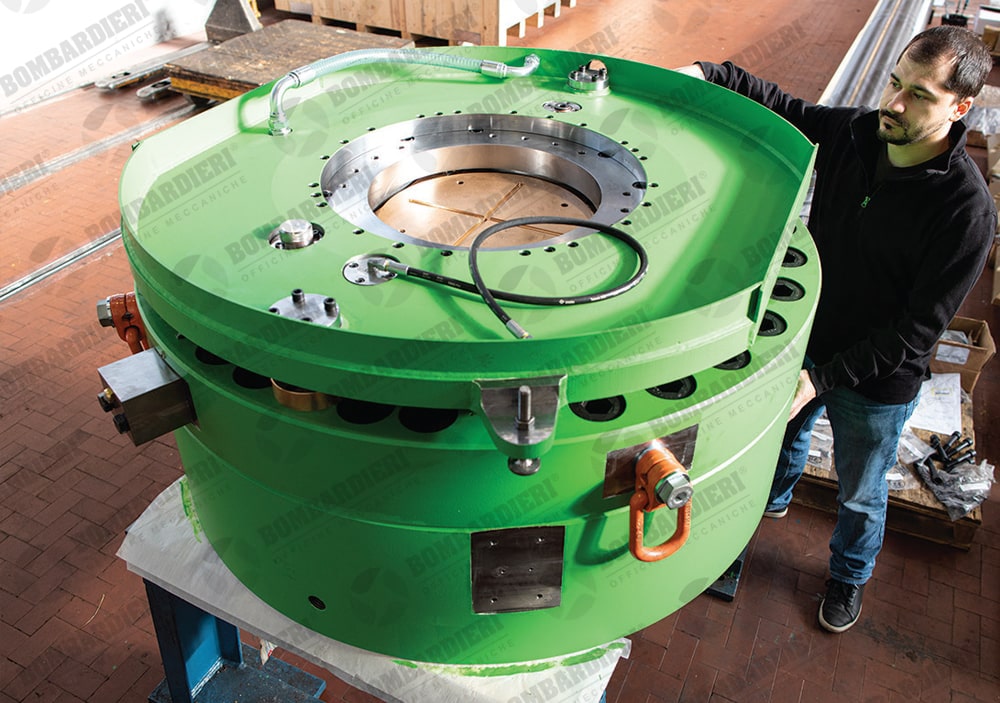

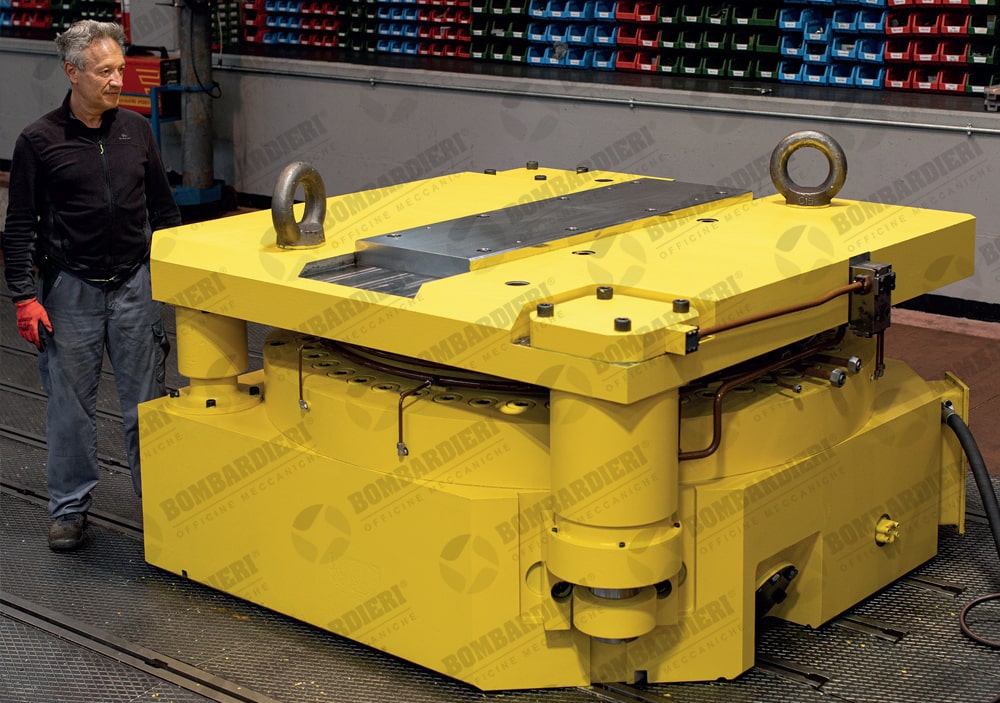

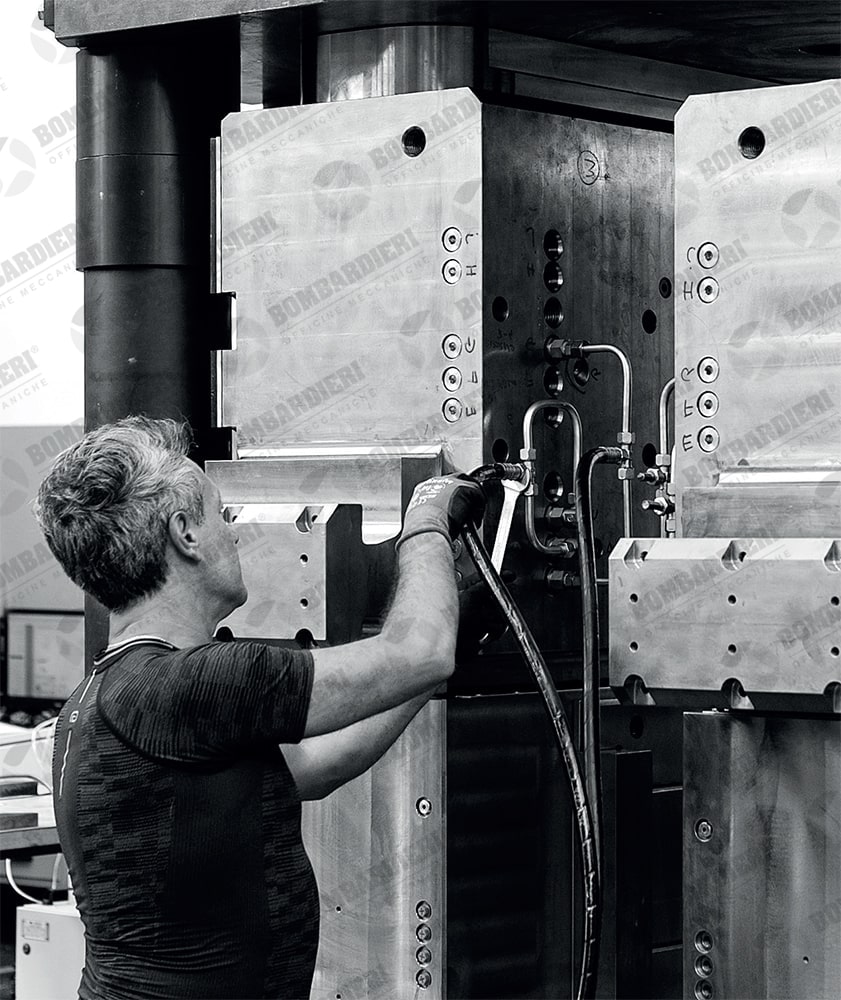

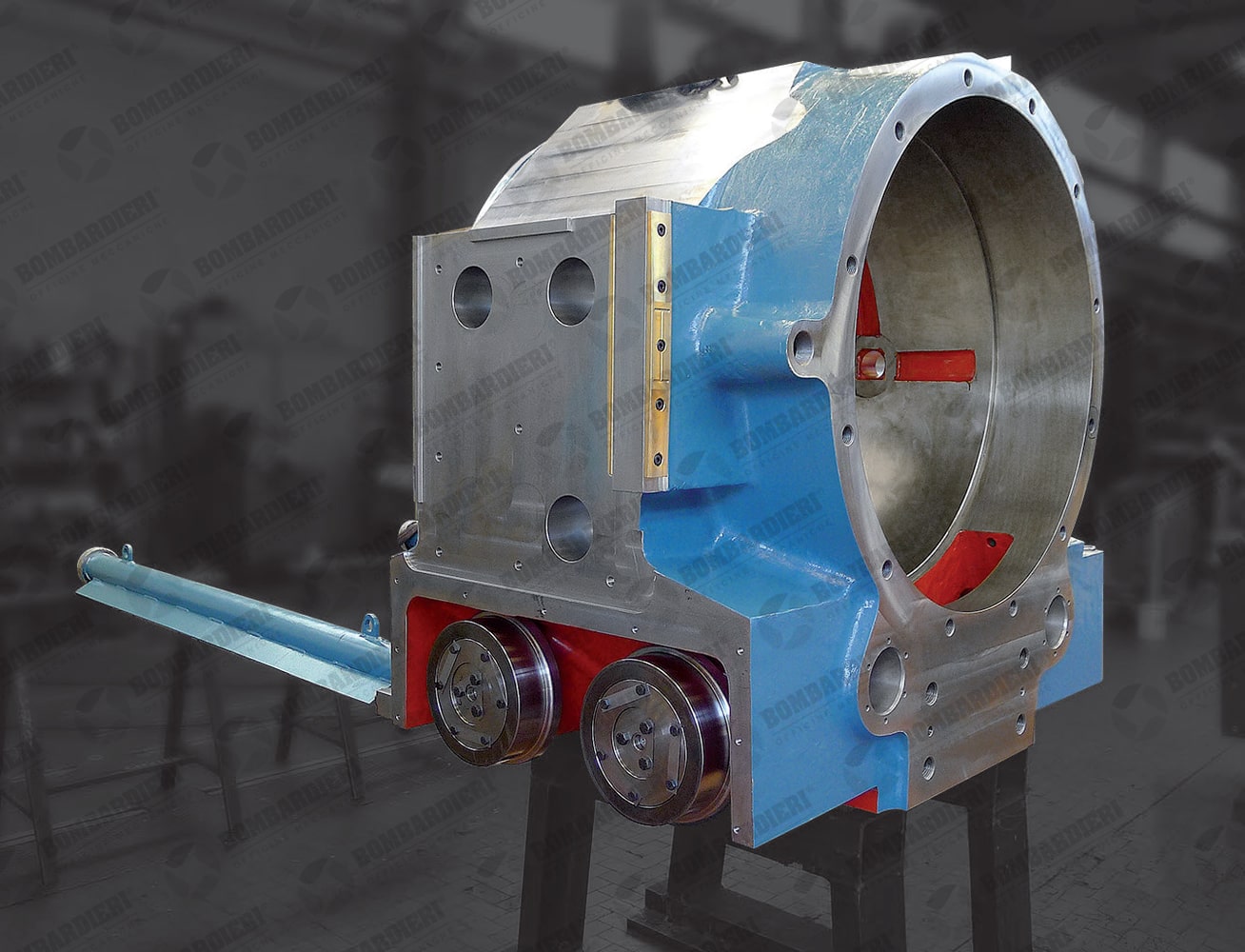

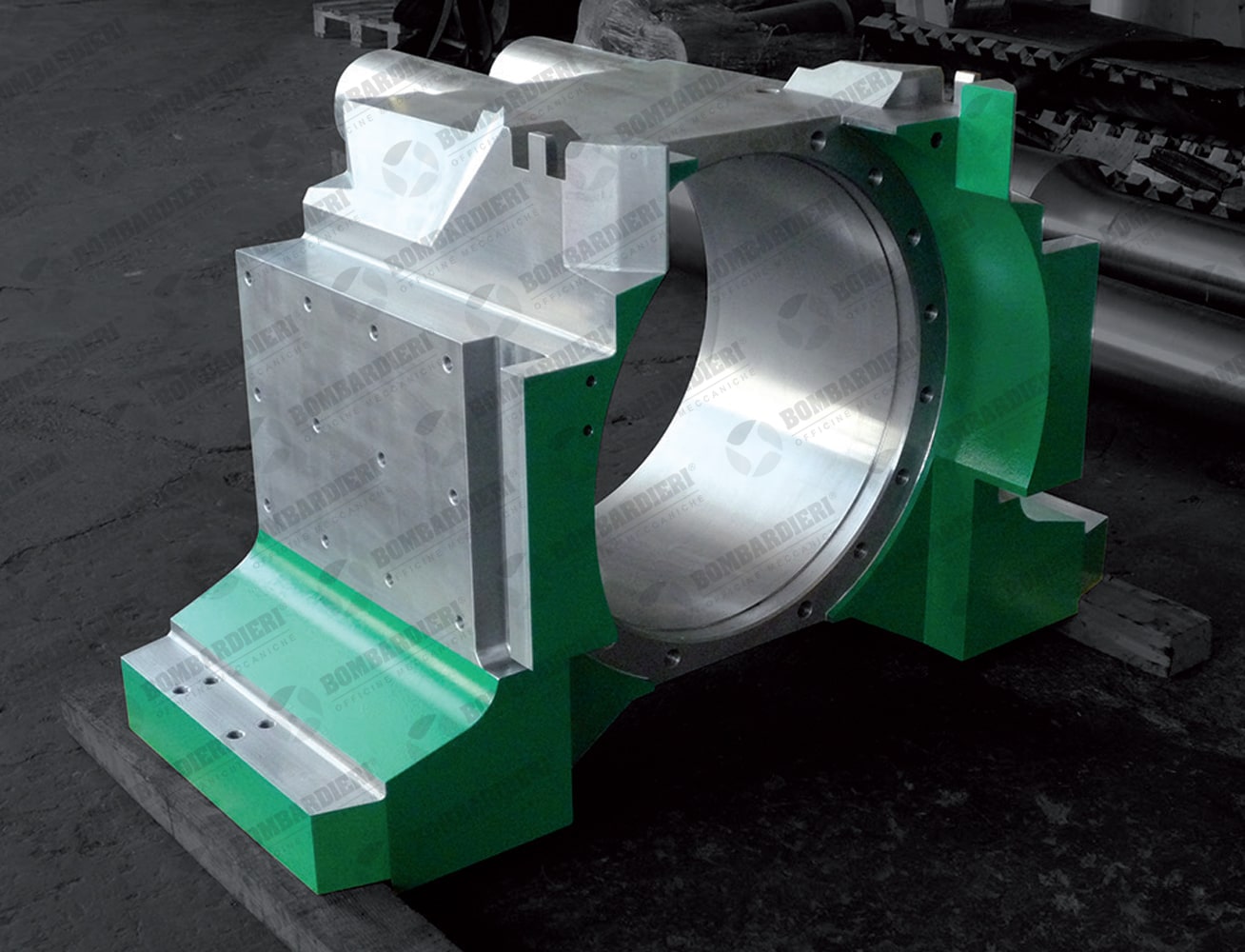

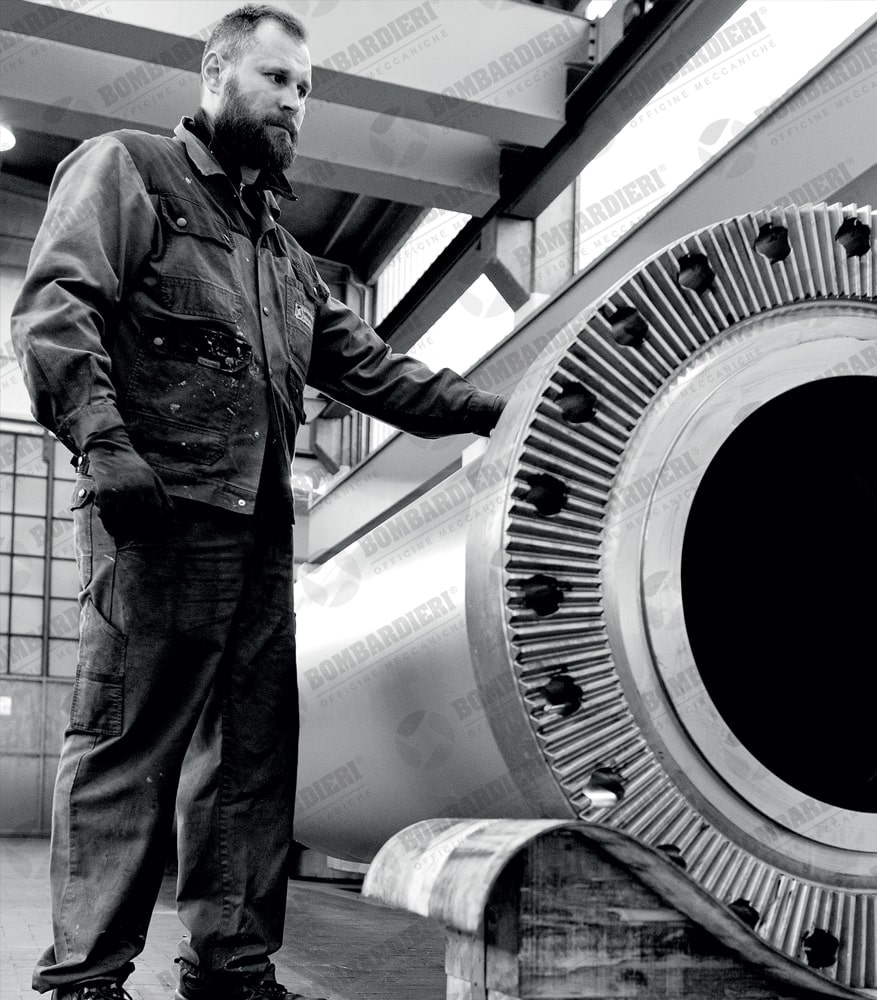

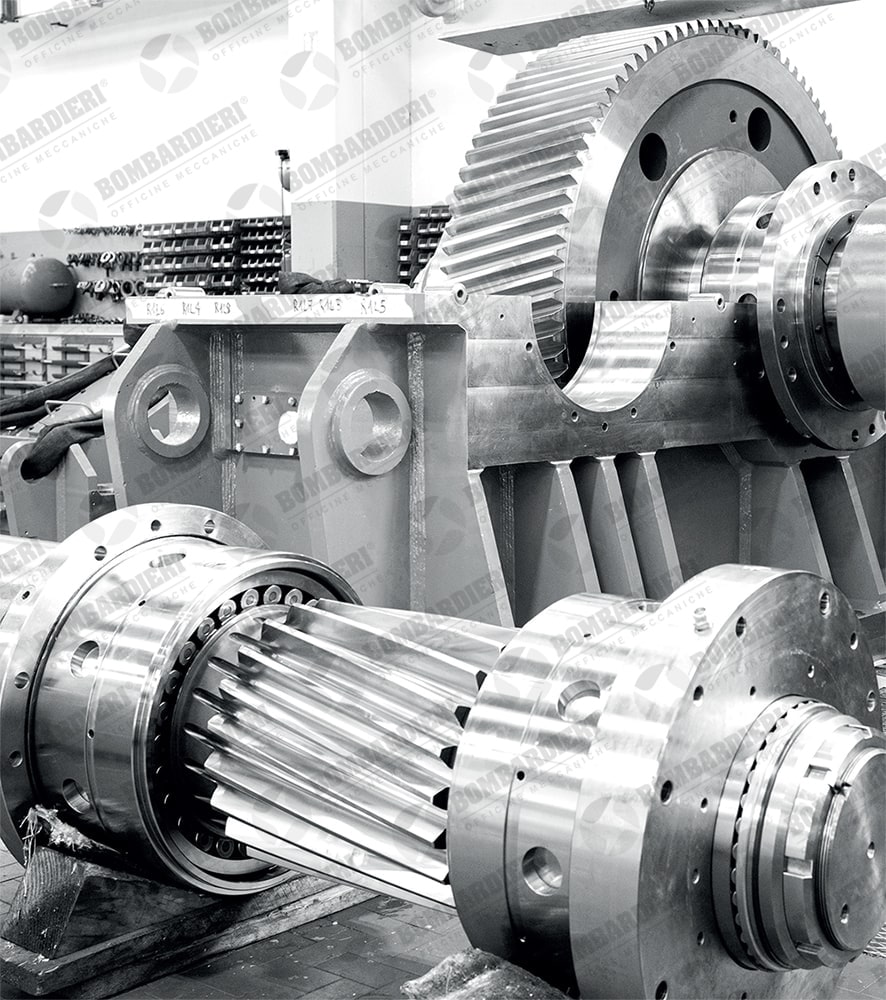

OUR PRODUCTION

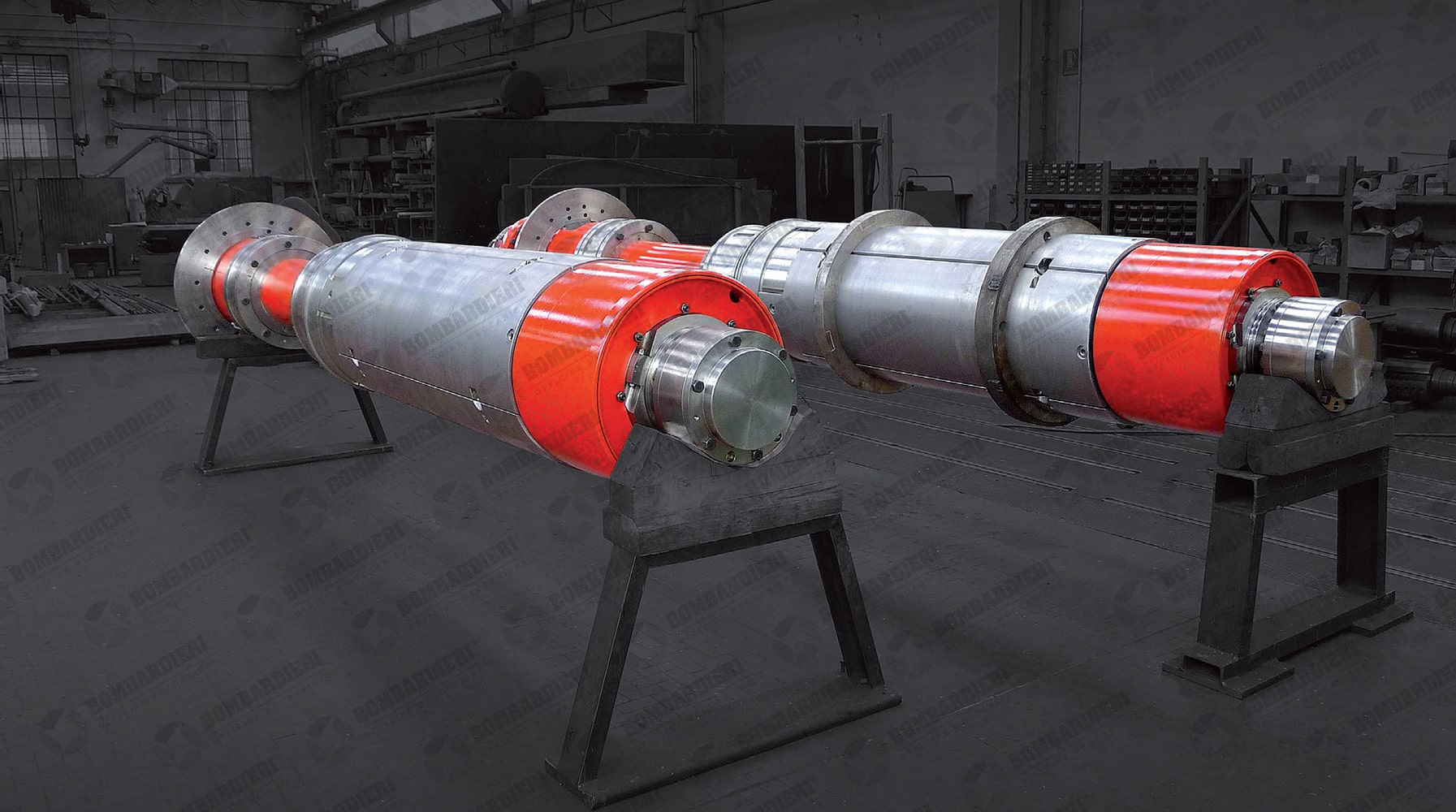

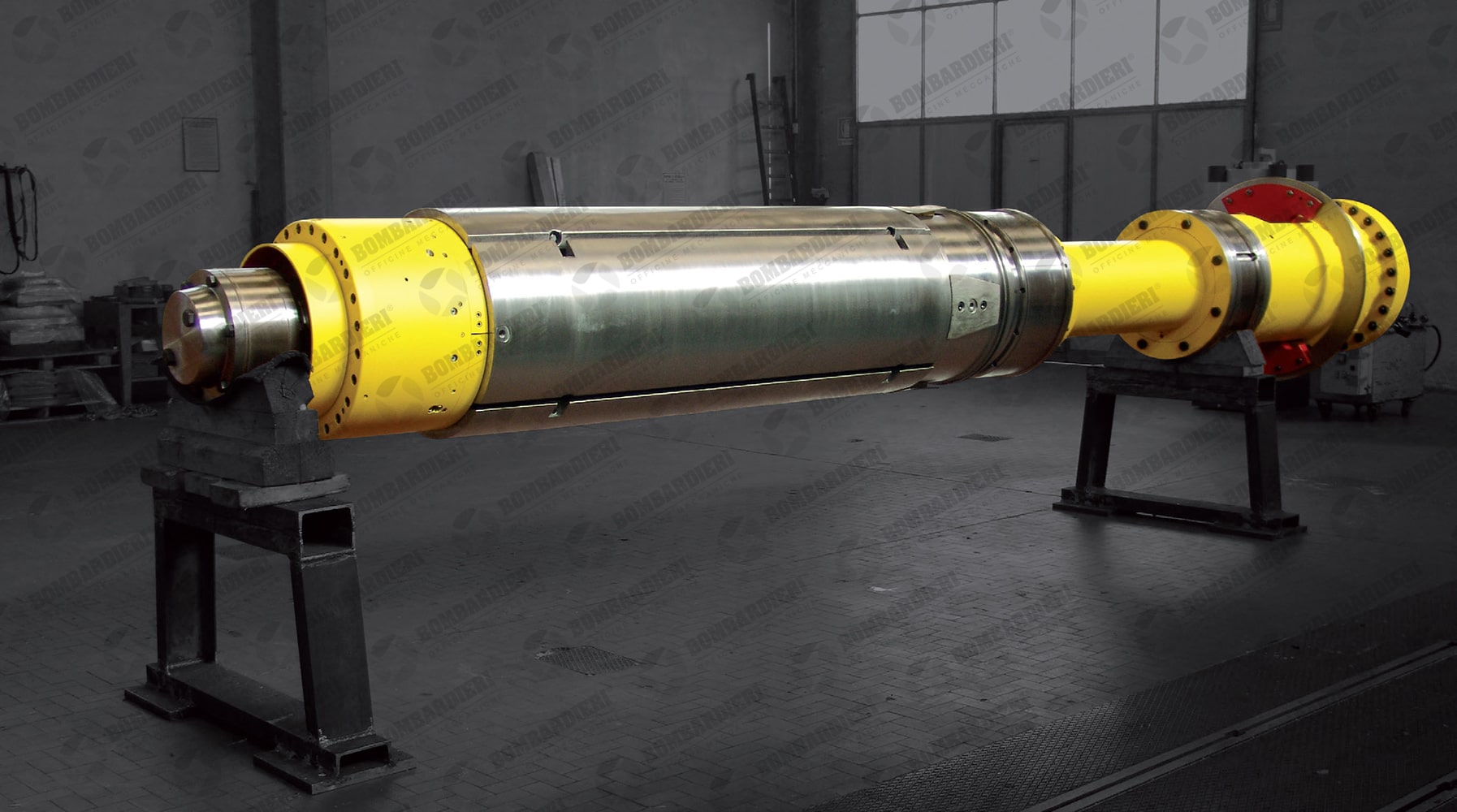

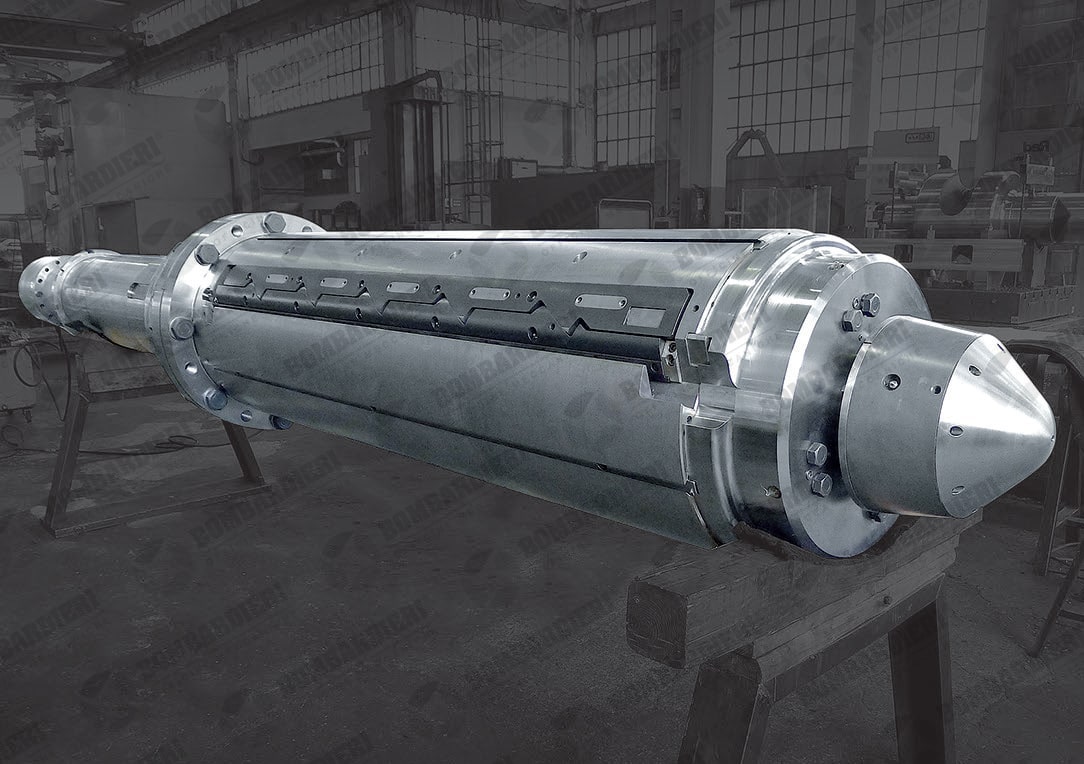

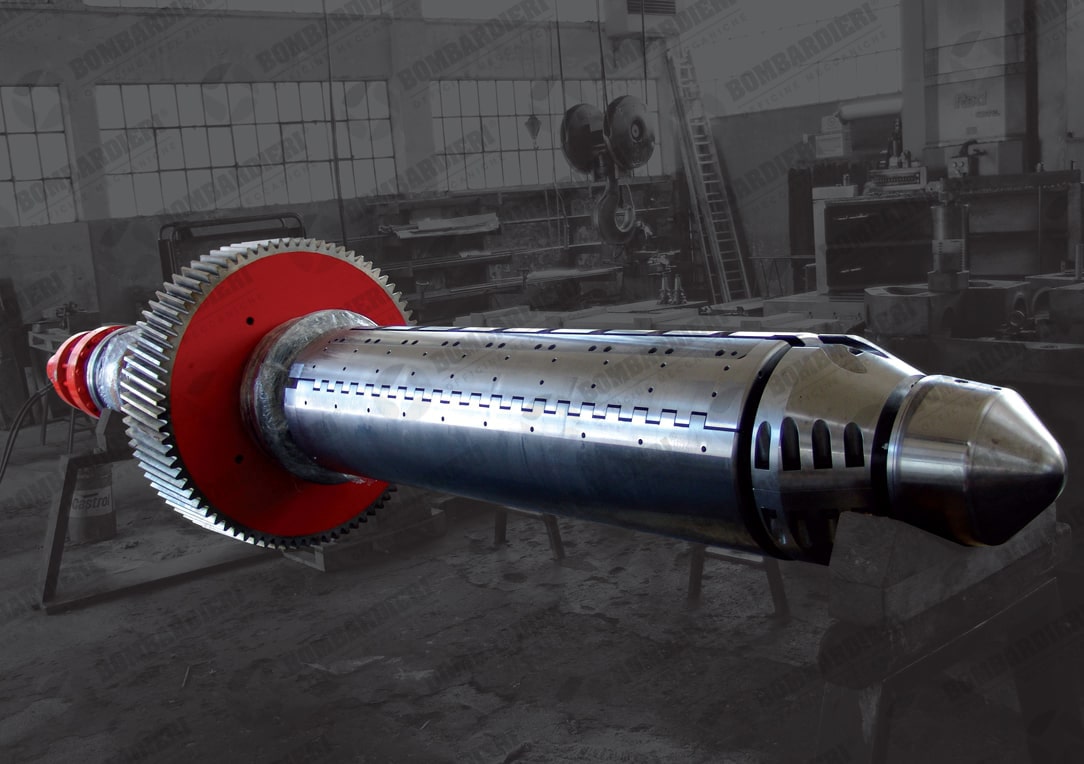

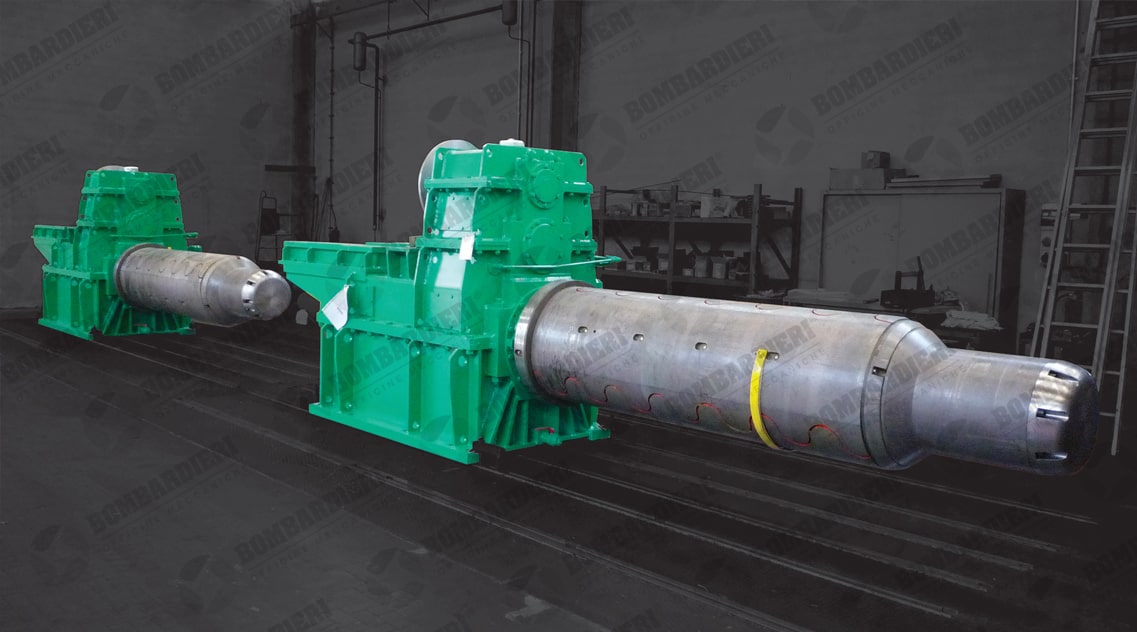

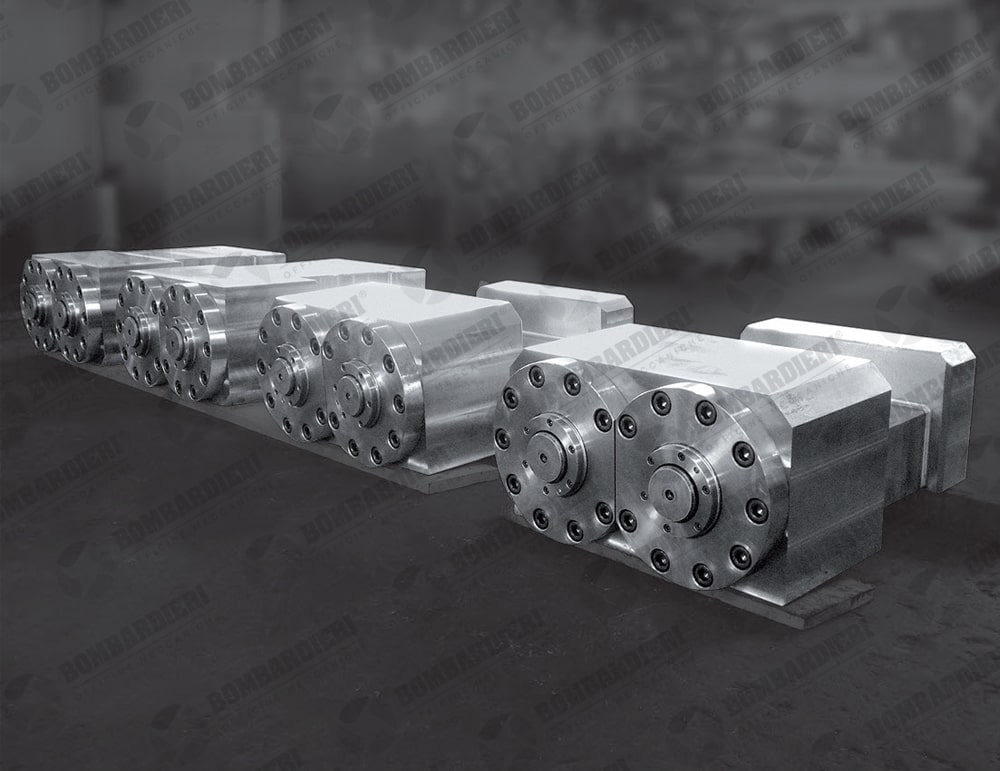

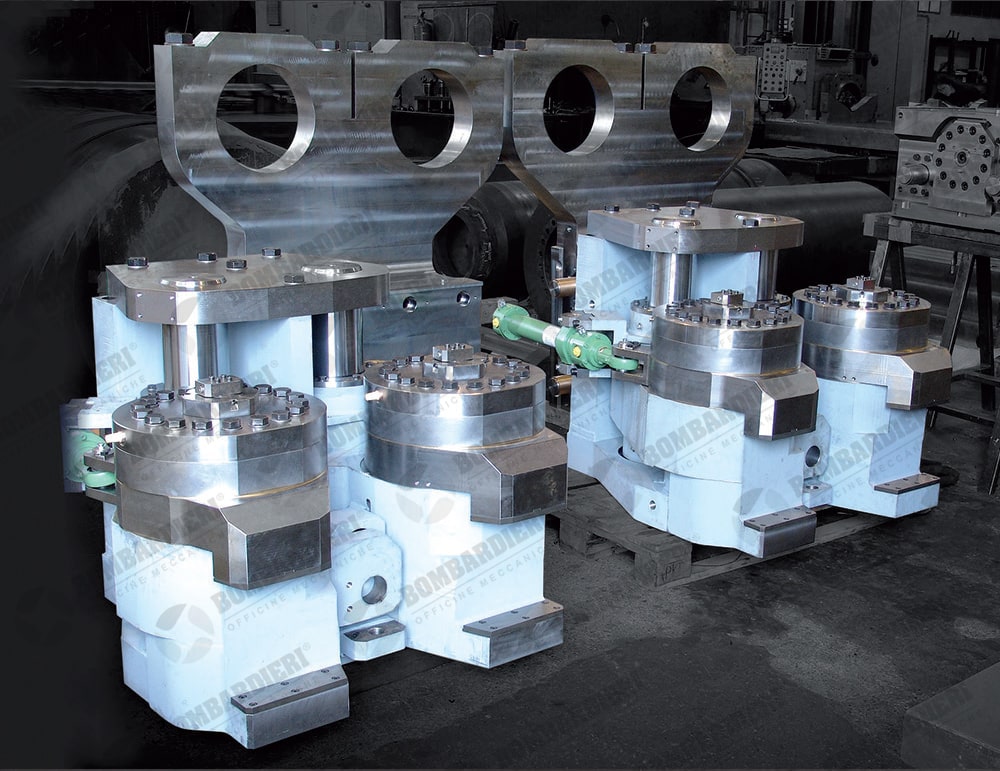

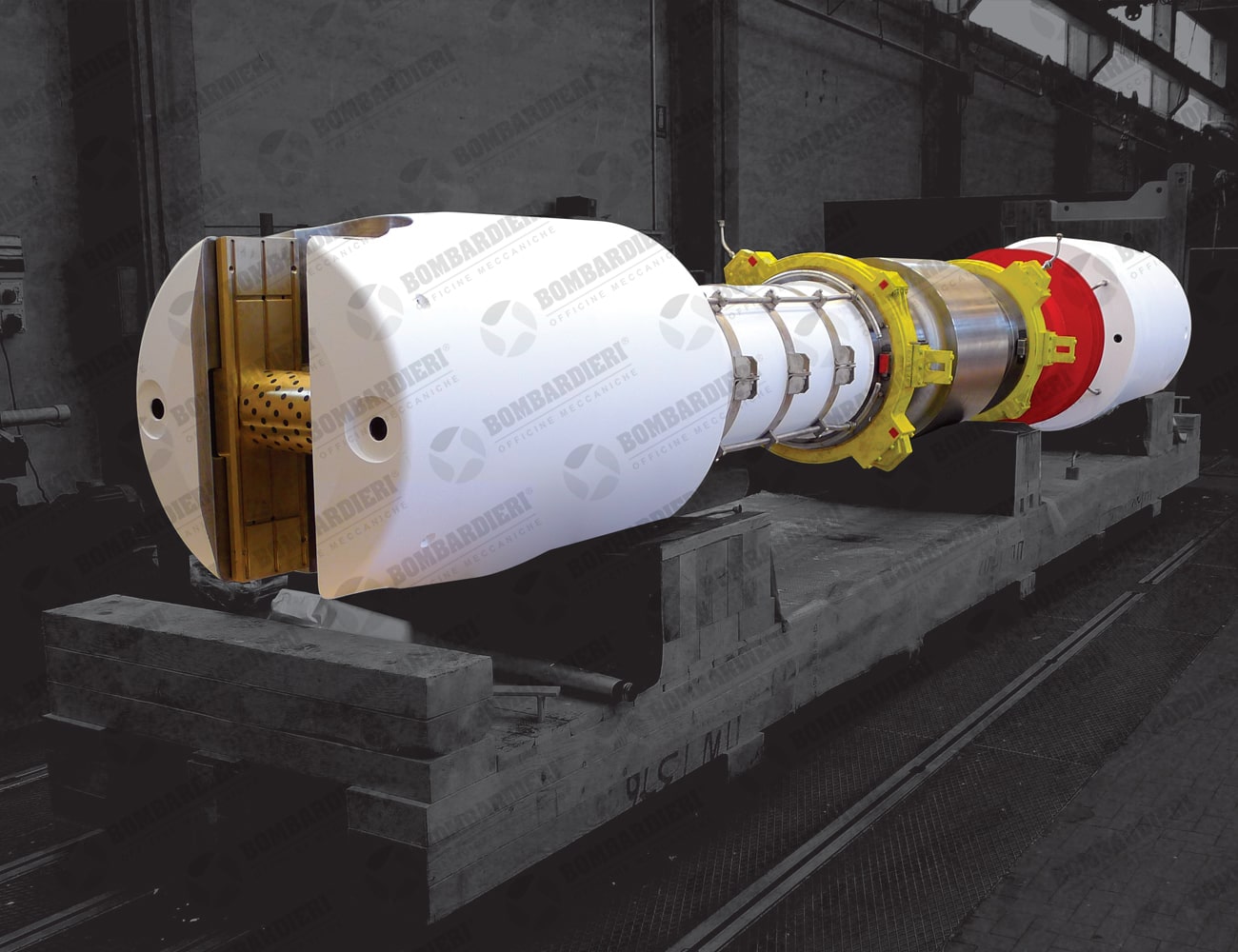

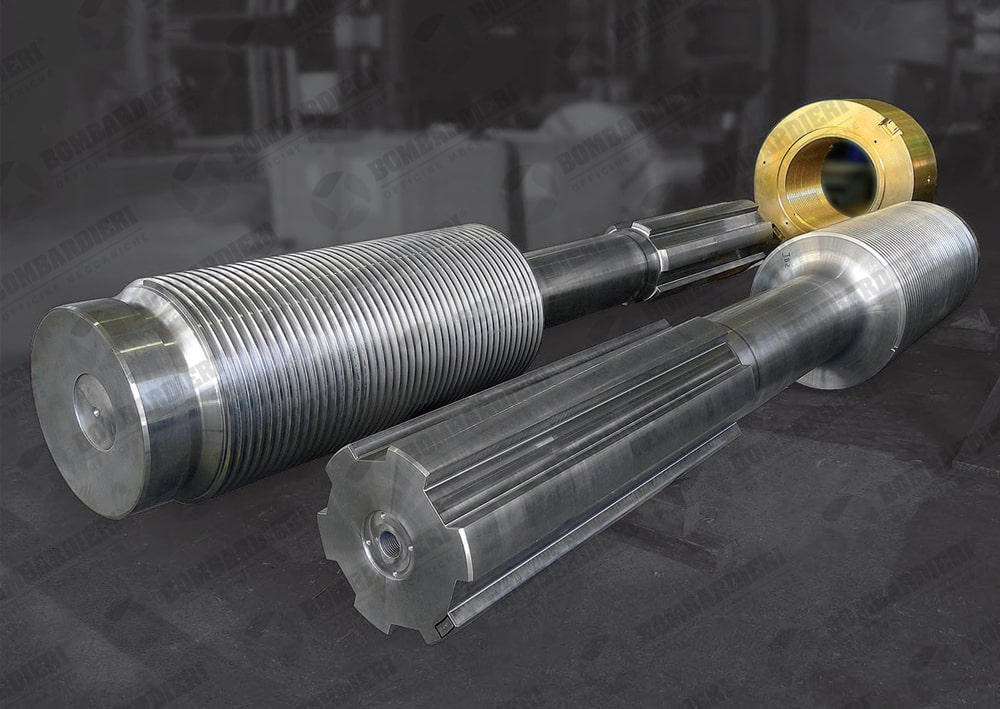

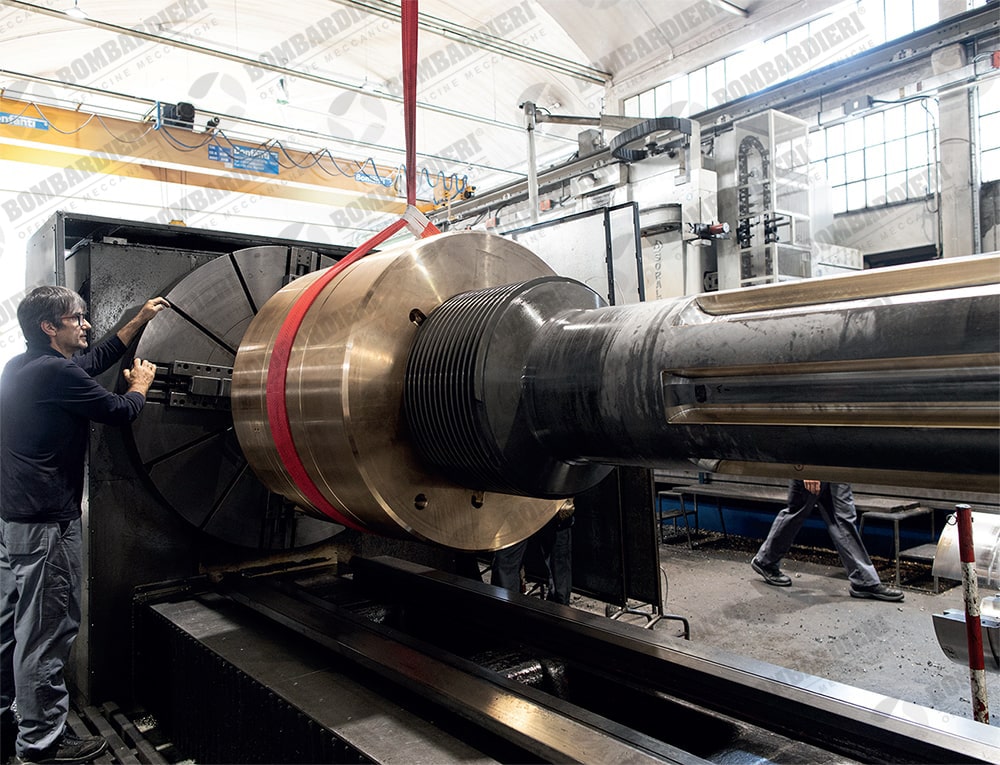

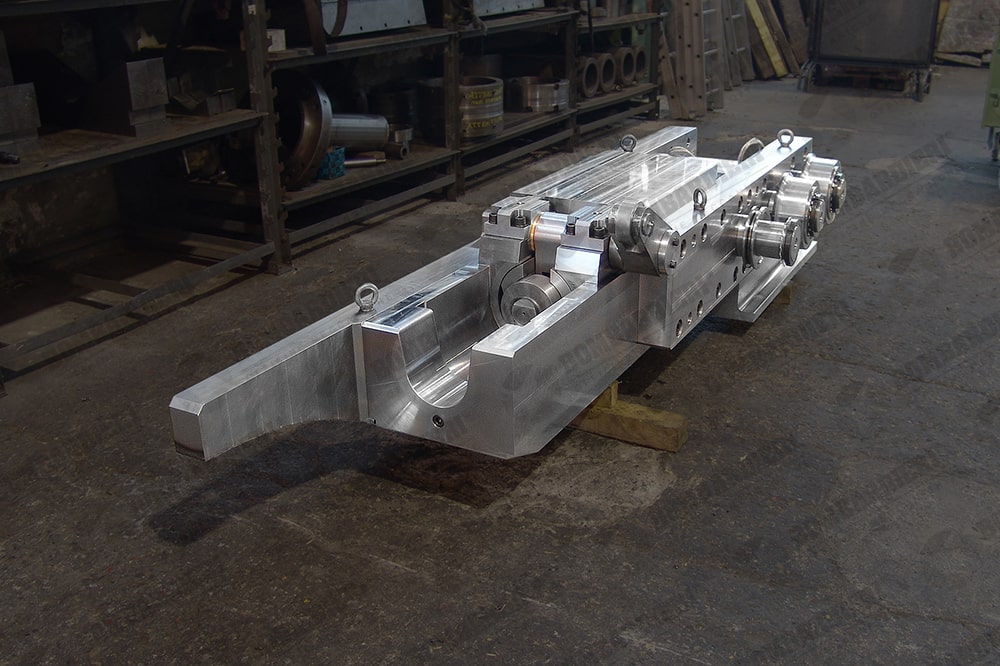

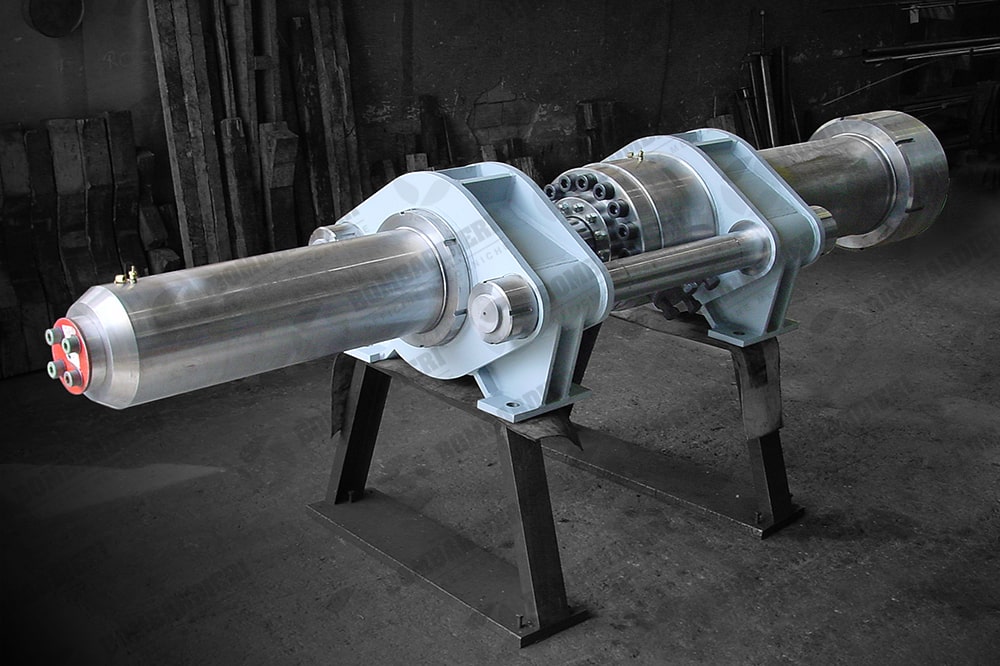

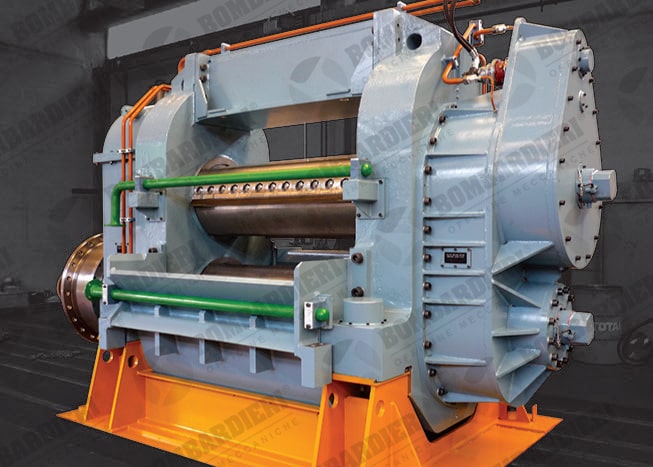

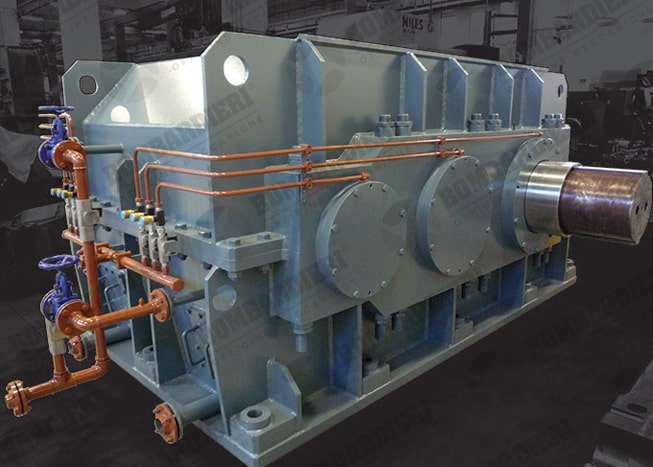

Stand-alone mandrels

Rear end of mandrel is equipped with a gear coupling, for connecting to the speed reducer. Mandrel bearings are supported by a dedicated frame. To replace the mandrel, the gear coupling is disconnected and bearing pillow blocks are opened.

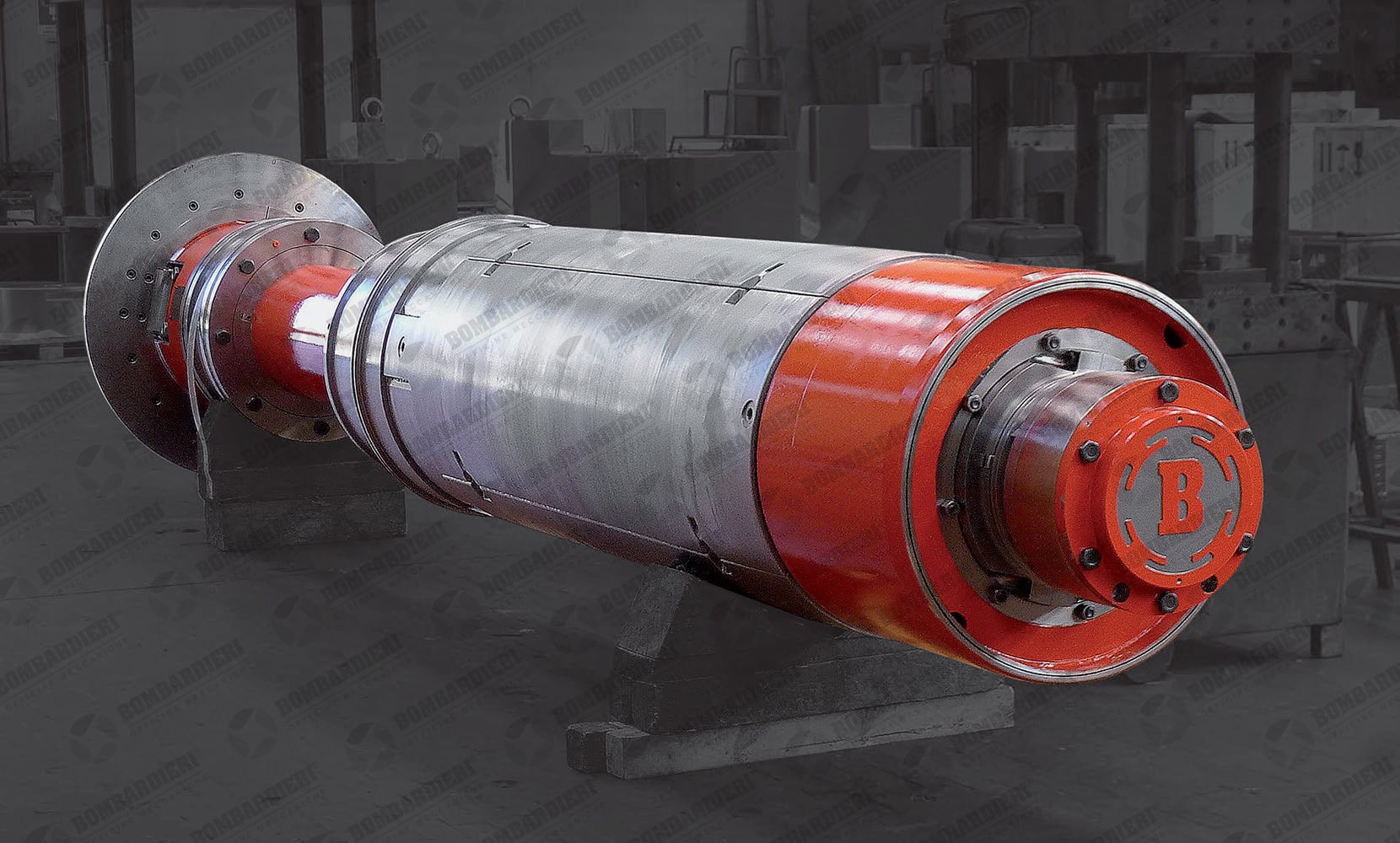

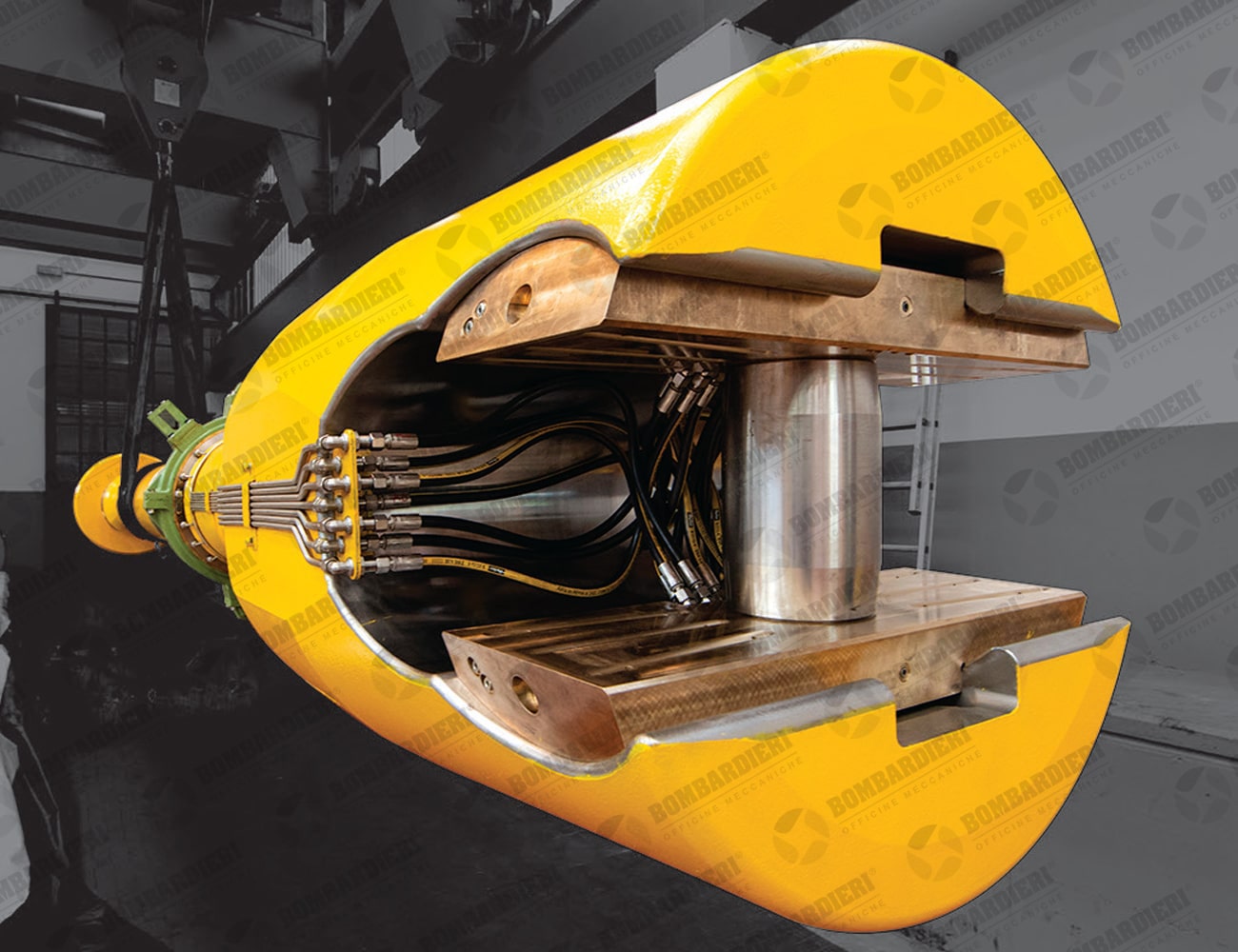

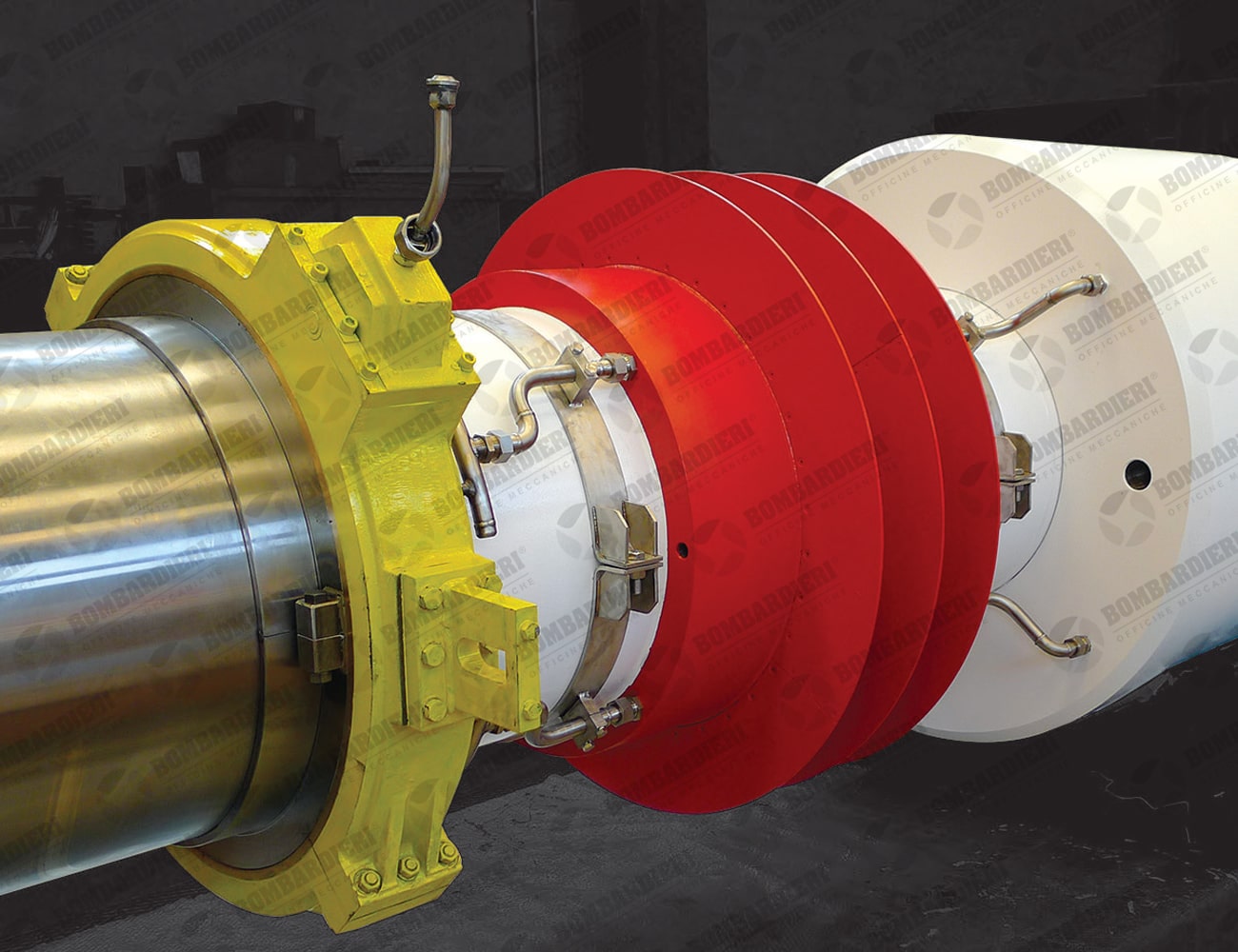

HOT ROLLING MANDREL

Hot rolling mill mandrels of different design with centralized lubrication.Stand-alone mandrels

Rear end of mandrel is equipped with a gear coupling, for connecting to the speed reducer. Mandrel bearings are supported by a dedicated frame. To replace the mandrel, the gear coupling is disconnected and bearing pillow blocks are opened.

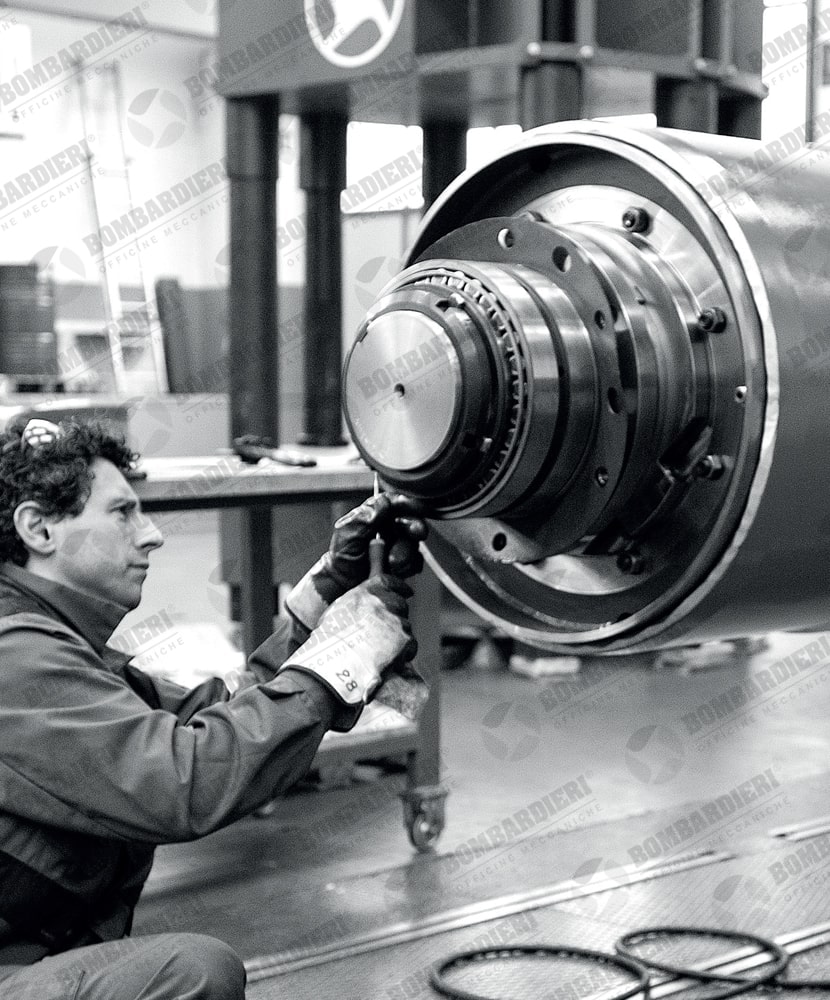

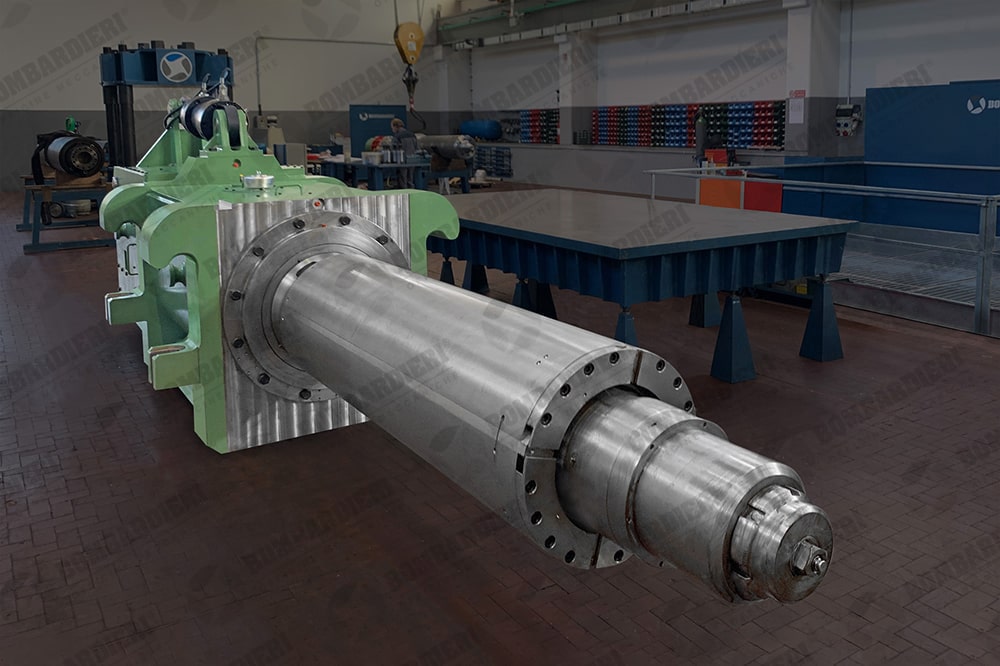

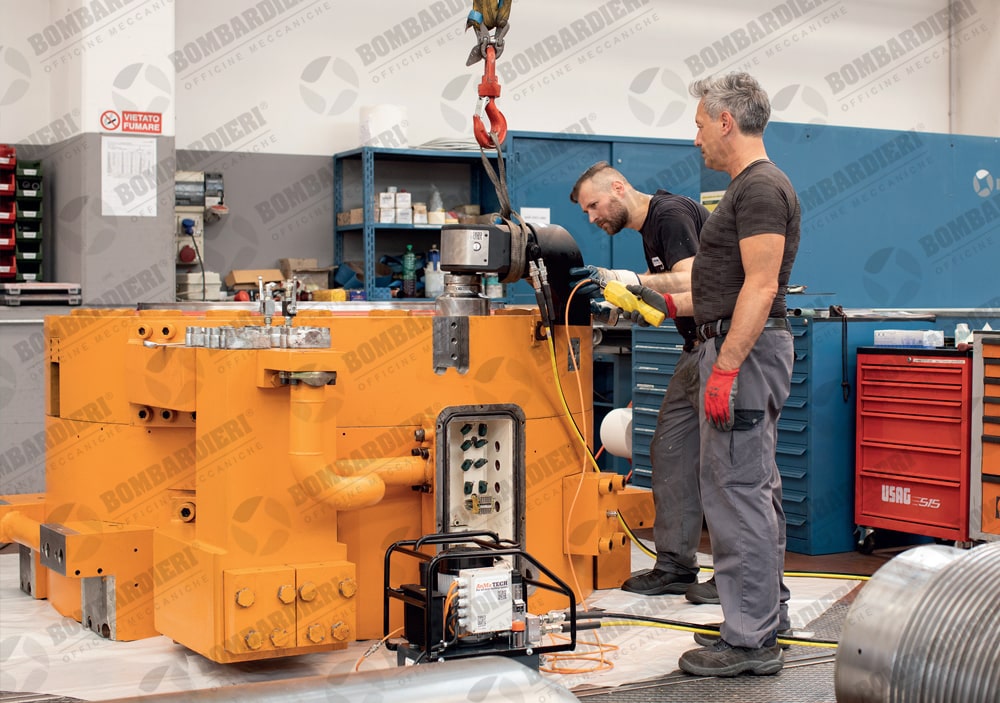

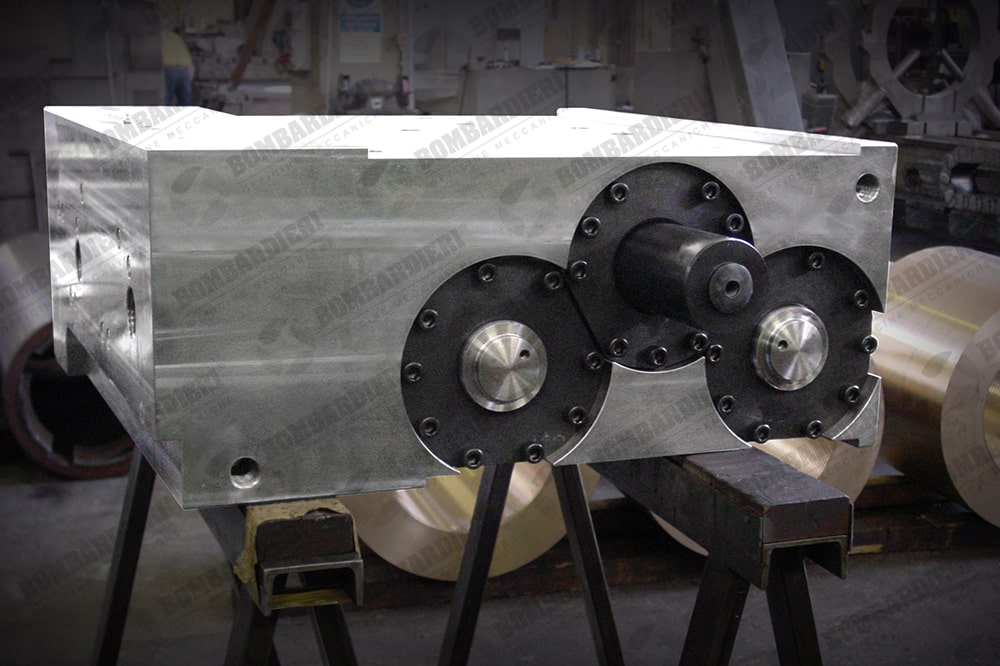

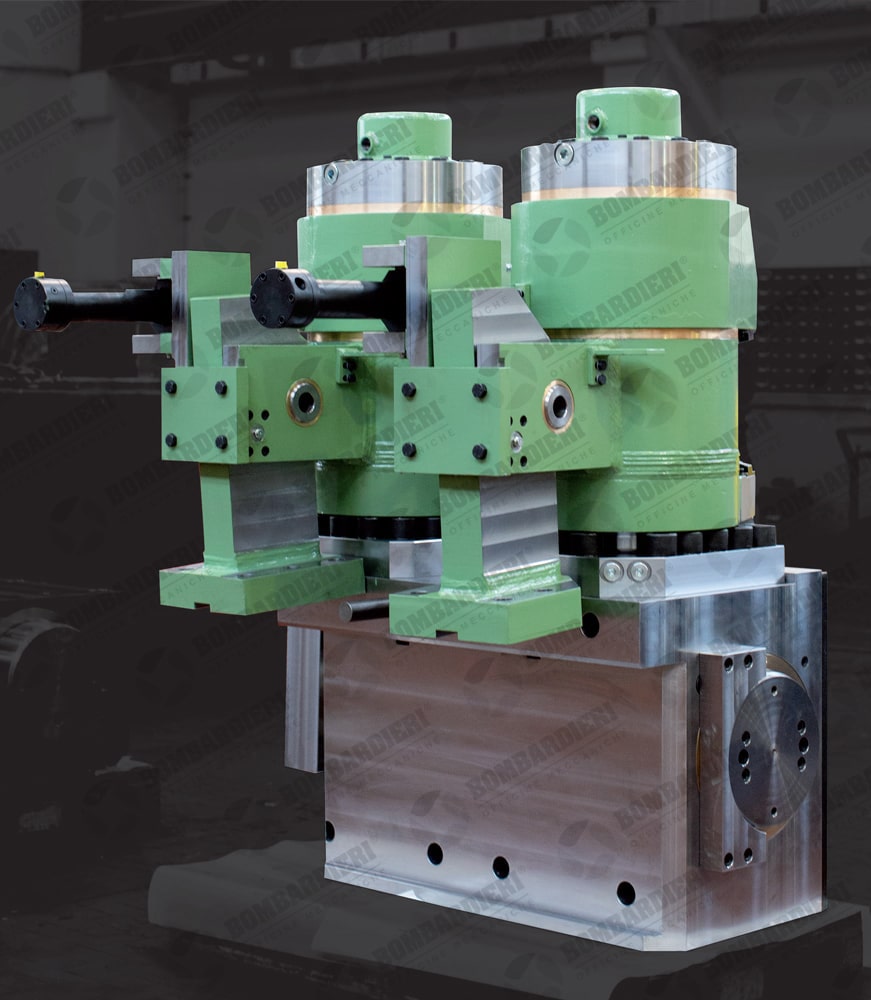

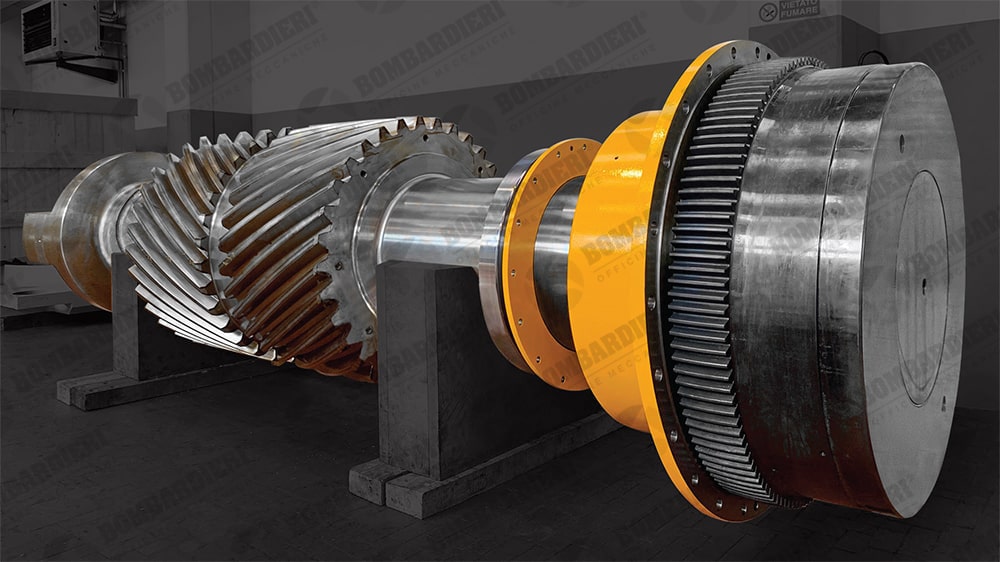

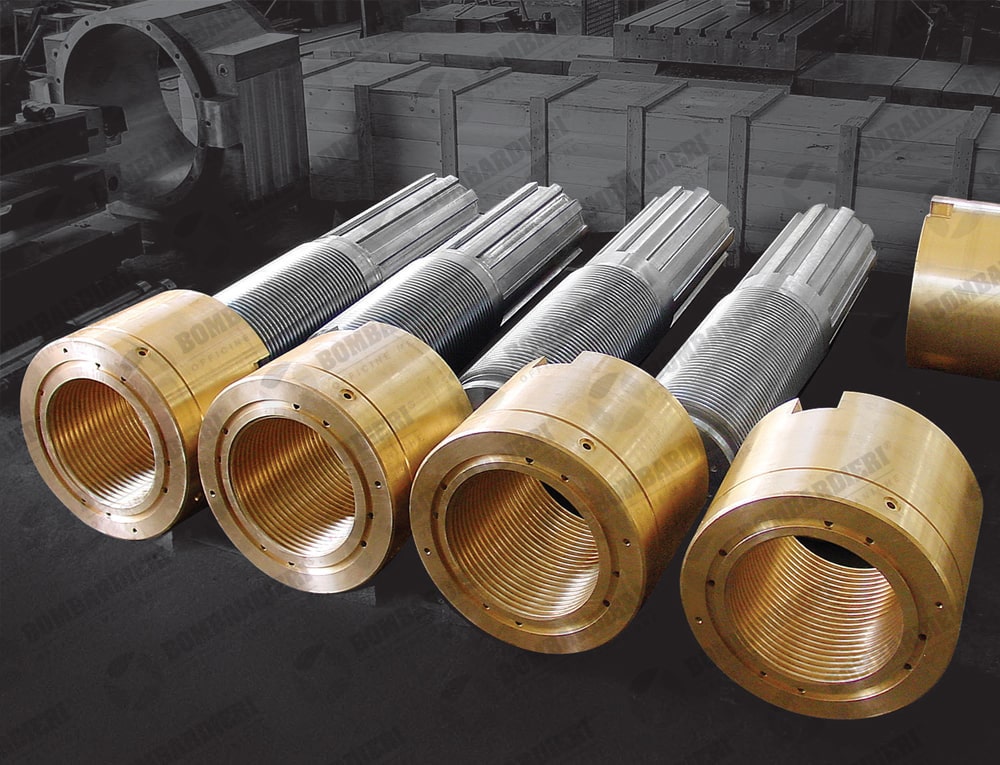

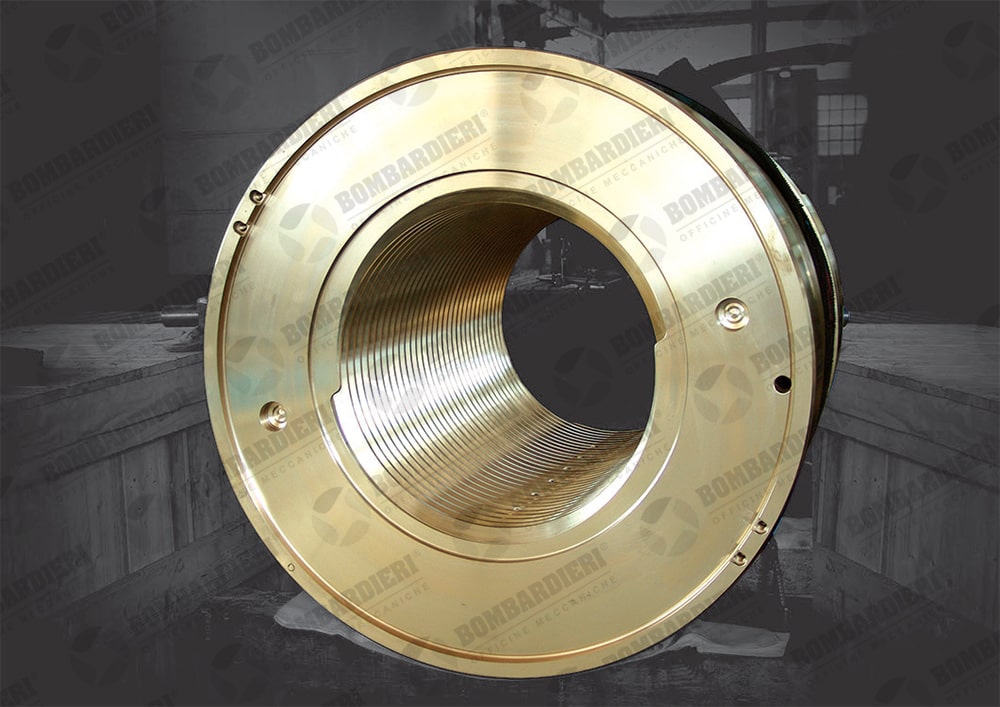

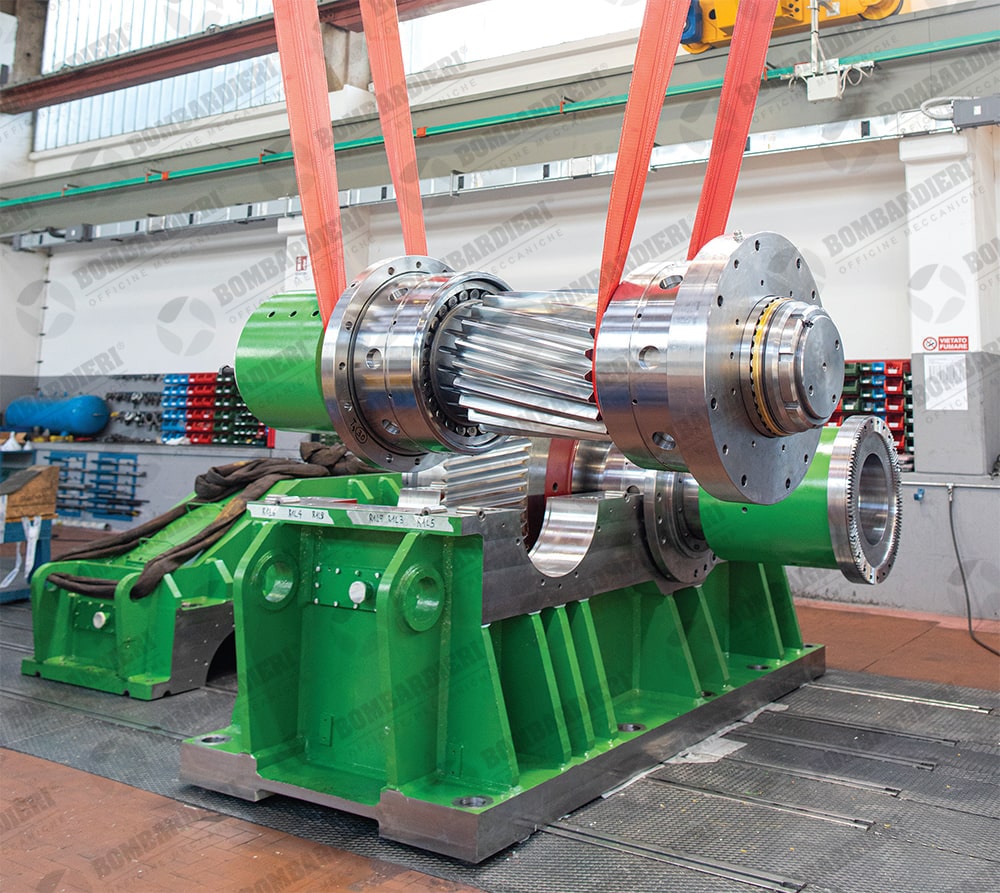

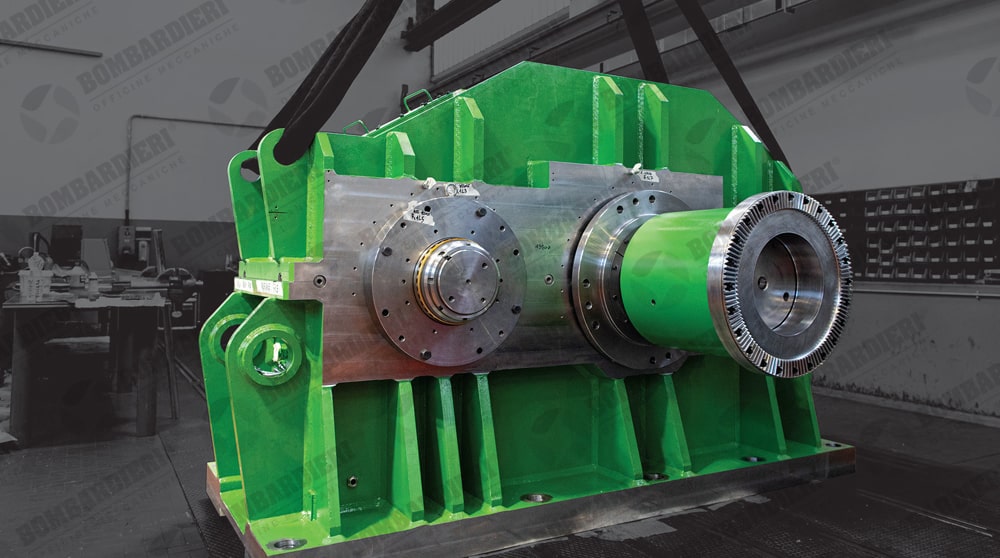

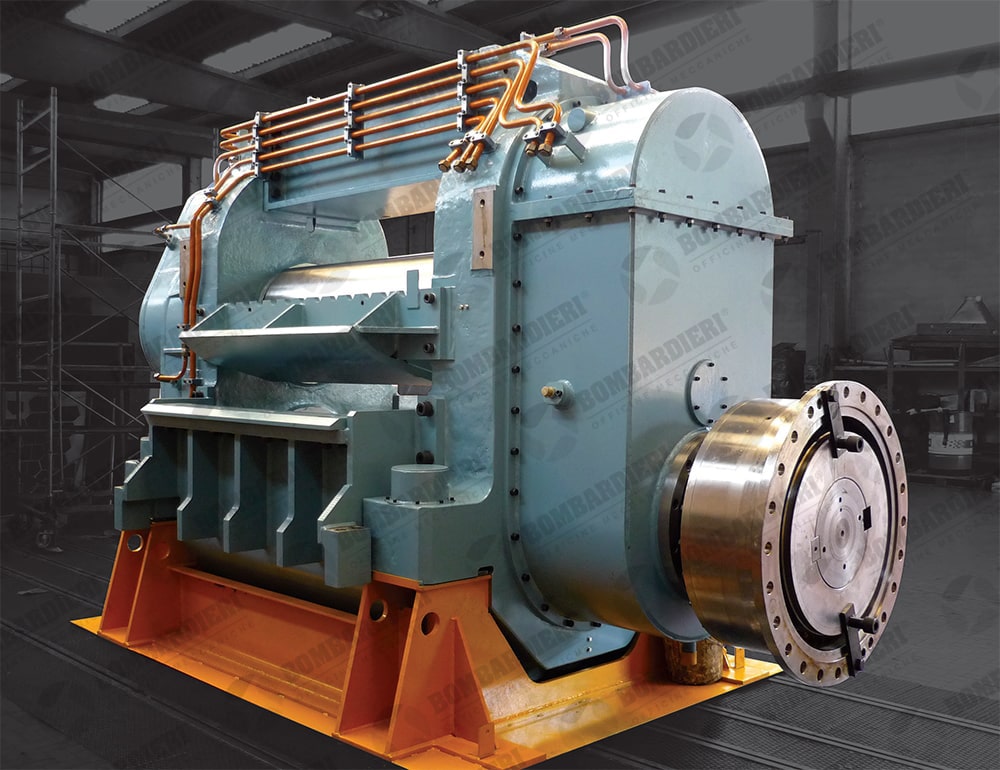

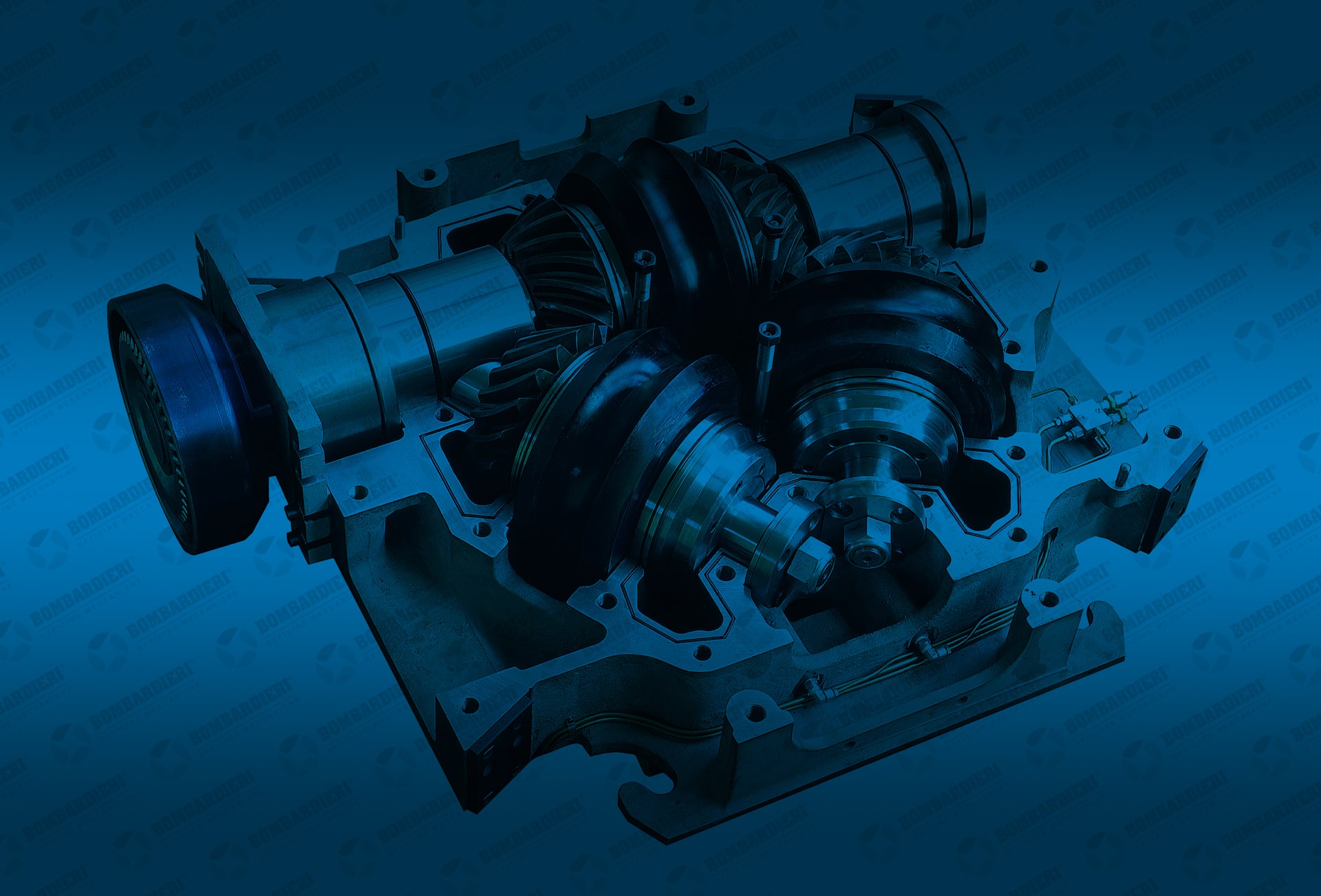

Plugin mandrels

Spline teeth are machined on the mandrel shaft, which match with the gearbox output hollow shaft.

Plugin mandrel can be extracted from the gearbox frontally.

More information